5 Reasons Why Best CNC Manufacturing Leads to Exceptional Product Quality

In the competitive landscape of modern manufacturing, CNC manufacturing stands out as a crucial driver of exceptional product quality. According to a report by Grand View Research, the global CNC machining market is projected to reach $100.27 billion by 2025, underscoring the significant demand for precision-engineered products across various industries. High-quality CNC manufacturing not only enhances productivity but also minimizes waste and reduces production time, making it a preferred choice among manufacturers. As companies increasingly adopt advanced CNC technologies, they unlock capabilities that lead to unparalleled precision and consistency in their products. This blog will explore five key reasons why investing in superior CNC manufacturing practices translates directly to exceptional product quality, ultimately ensuring customer satisfaction and driving business success.

In the competitive landscape of modern manufacturing, CNC manufacturing stands out as a crucial driver of exceptional product quality. According to a report by Grand View Research, the global CNC machining market is projected to reach $100.27 billion by 2025, underscoring the significant demand for precision-engineered products across various industries. High-quality CNC manufacturing not only enhances productivity but also minimizes waste and reduces production time, making it a preferred choice among manufacturers. As companies increasingly adopt advanced CNC technologies, they unlock capabilities that lead to unparalleled precision and consistency in their products. This blog will explore five key reasons why investing in superior CNC manufacturing practices translates directly to exceptional product quality, ultimately ensuring customer satisfaction and driving business success.

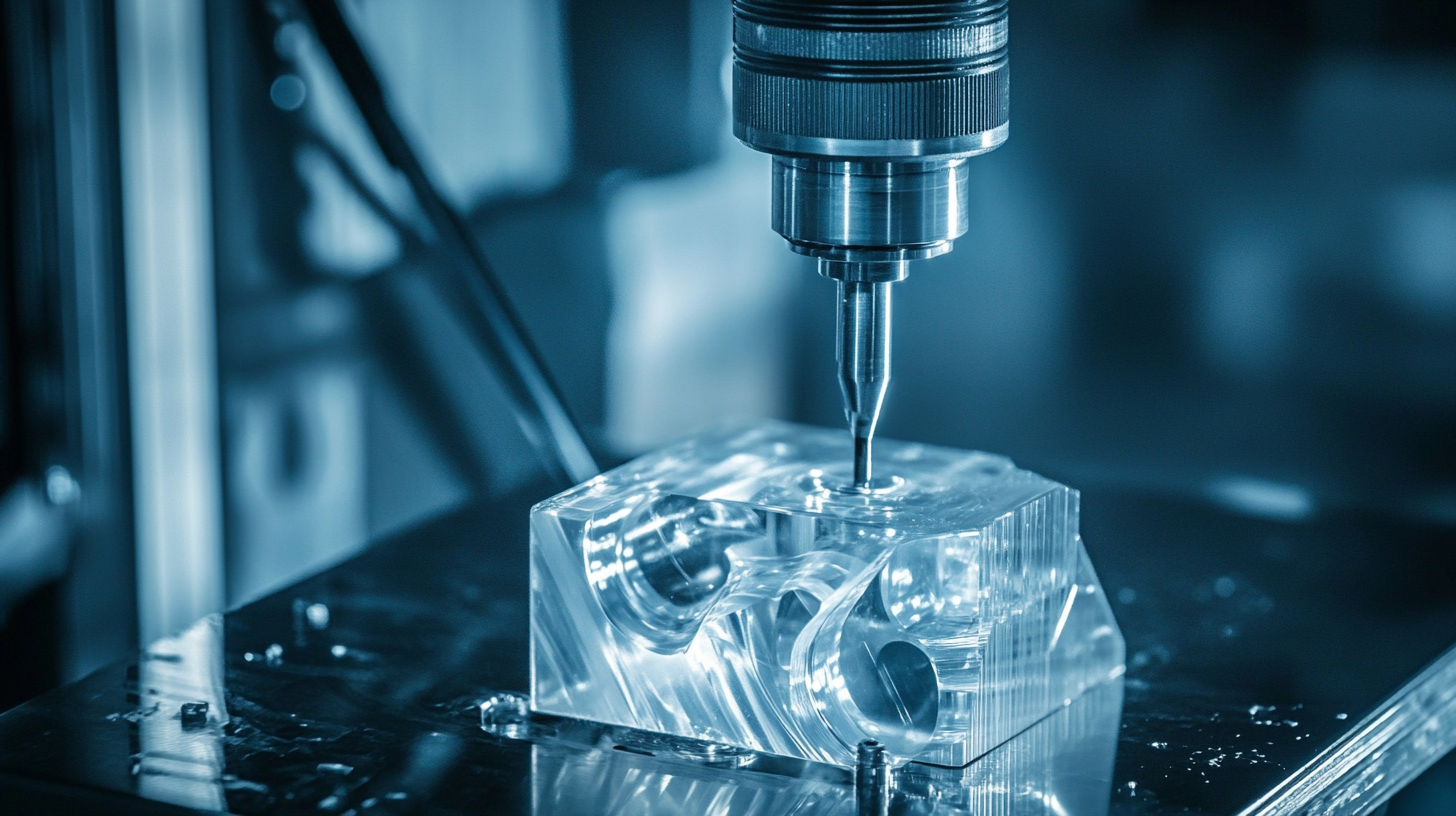

The Critical Role of Precision in CNC Manufacturing for Product Quality

In today’s competitive manufacturing landscape, precision plays a pivotal role in ensuring exceptional product quality, particularly in CNC (Computer Numerical Control) manufacturing. As industries grow increasingly reliant on technology, the demand for high-quality, precise components continues to surge. This is exemplified by the projected growth of the global CNC machine market, which is expected to rise significantly from $101.22 billion in 2025 to $195.59 billion by 2032, with a compound annual growth rate of 9.9%. Such expansion highlights the critical importance of accuracy in the production processes, ultimately influencing the overall performance and reliability of end products.

Moreover, specific sectors such as oil and gas, automotive, and aerospace heavily depend on advanced drilling applications that prioritize precision and efficiency. The deep hole drilling machine segment alone is anticipated to grow from $7.69 billion in 2023 to $11 billion by 2032. This surge indicates that industries are increasingly adopting advanced CNC technologies to meet stringent quality standards while streamlining production. As we navigate through the fourth industrial revolution, the integration of digital and intelligent technologies in manufacturing will further enhance the capacity for precision, leading to superior product quality and greater consumer satisfaction.

5 Reasons Why Best CNC Manufacturing Leads to Exceptional Product Quality

| Reason | Description | Impact on Product Quality |

|---|---|---|

| Precision Cutting | CNC machines use precise cutting tools that minimize errors during manufacturing. | Reduces material waste and ensures tight tolerances. |

| Consistent Reproduction | CNC technology allows for consistent replication of parts, maintaining quality across large batches. | Ensures each product meets specifications, enhancing reliability. |

| Advanced Materials | CNC manufacturing can work with a wide range of advanced materials, promoting innovation. | Enables the creation of higher-performance products. |

| Speed of Production | CNC machining offers speed in production without compromising quality. | Faster time to market while maintaining quality control. |

| Quality Control Processes | Integrated quality control systems monitor processes, ensuring output meets standards. | Reduces defects and enhances trust in product integrity. |

Assessing Material Consistency: How CNC Machining Reduces Variability

CNC machining stands out as a leading method in manufacturing due to its ability to consistently produce high-quality parts with minimal variability. One of the critical aspects that contribute to exceptional product quality is the assessment of material consistency. CNC machines operate with precision, utilizing advanced software that allows manufacturers to select the best materials for their projects. By controlling all variables during the machining process, unnecessary fluctuations in product quality can be significantly reduced.

Tips for ensuring material consistency include sourcing high-grade raw materials from reputable suppliers and conducting thorough inspections before production begins. Additionally, implementing quality control measures throughout the machining process helps identify and rectify any discrepancies early on. Regular maintenance of CNC machines is also vital, as it ensures that the equipment operates at peak performance, further minimizing the risk of variability.

Moreover, consistent programming and the use of standardized processes can enhance quality assurance in CNC machining. Adopting this structured approach enables manufacturers to replicate successful outcomes across different production runs. By focusing on these strategies, manufacturers can leverage CNC machining to achieve superior product quality reliably, ultimately leading to greater customer satisfaction and loyalty.

The Impact of Advanced Technology on CNC Production Accuracy

Advanced technology is significantly shaping the landscape of CNC manufacturing, enhancing production accuracy and ultimately leading to exceptional product quality. The global CNC machine market is projected to experience substantial growth, rising from $101.22 billion in 2025 to an estimated $195.59 billion by 2032, with a compound annual growth rate (CAGR) of 9.9%. This growth is primarily driven by an increased demand for precision and automation in manufacturing processes. As manufacturers adopt more advanced CNC machines, the level of accuracy in production is set to improve, resulting in higher quality products that meet stringent industry standards.

Moreover, the rise of Industry 4.0 has further accelerated this trend by integrating automation, data exchange, and smart technologies into the manufacturing process. For instance, the market for CNC horizontal machining centers is expected to grow by USD 2.67 billion from 2024 to 2028, largely propelled by the demand for precision manufacturing and the implementation of artificial intelligence. Such technologies enable self-optimization in machining processes, enhancing efficiency and accuracy. As a result, businesses leveraging these advancements are poised to deliver superior product quality and maintain a competitive edge in an increasingly dynamic marketplace.

Quality Control Standards: How CNC Manufacturing Ensures Exceptional Products

In the realm of CNC manufacturing, quality control standards play a crucial role in ensuring exceptional product quality. The integration of digital twin technology has emerged as a game-changer, enabling manufacturers to simulate processes before physical production. This ensures that products are manufactured right the first time, reducing errors and minimizing costs. According to a recent industry report, implementing digital twins can increase production efficiency by up to 30%, highlighting the significance of technological advancements in maintaining quality standards.

Moreover, leveraging artificial intelligence in quality control processes further enhances product integrity. AI systems can analyze vast amounts of data in real-time, allowing for immediate detection of anomalies and ensuring that only products meeting high-quality benchmarks proceed to the next stages. Research indicates that AI-driven quality control can reduce defect rates by approximately 25%, demonstrating its critical impact on product excellence.

**Tip:** To maximize quality control in CNC manufacturing, consider adopting both digital twin technology and AI analytics. Regularly review performance metrics and invest in employee training to adapt to these innovations. This proactive approach not only streamlines production but also reinforces a commitment to quality, ultimately driving customer satisfaction.

Real-World Case Studies: CNC Successes in Achieving Superior Quality Metrics

CNC manufacturing has proven to be a game-changer in achieving exceptional product quality across various industries. One significant example is the automotive sector, where precision and consistency are paramount. Manufacturers that implemented advanced CNC machining techniques reported a 30% reduction in defect rates, leading to higher customer satisfaction and loyalty. By focusing on automated processes, companies can ensure that each part meets stringent quality standards.

To achieve similar success, businesses should consider investing in regular training for their CNC operators. Empowering your team with the latest skills in CNC technology pays off, as it enhances their understanding of machine capabilities and optimizes performance. Another crucial tip is to incorporate rigorous quality control measures throughout the production process. Engaging in real-time monitoring allows for immediate adjustments, ensuring product specifications are consistently met.

Additionally, collaboration with CNC technology providers can provide insights into best practices and the latest innovations. Companies that maintain strong partnerships often report improved efficiency and product quality. Leveraging these relationships can lead to the integration of cutting-edge technologies that further elevate manufacturing standards, ultimately resulting in outstanding product quality.

5 Reasons Why Best CNC Manufacturing Leads to Exceptional Product Quality

This chart illustrates the impact of key factors in CNC manufacturing on product quality metrics based on industry data.