How to Choose the Right CNC Equipment for Your Manufacturing Needs

In the rapidly evolving manufacturing landscape, selecting the appropriate CNC equipment is crucial for optimizing production efficiency and maintaining competitive advantage. According to a recent report by MarketsandMarkets, the global CNC machine market is projected to reach $80.6 billion by 2023, driven by the increasing demand for precision machining and automation in various industries. The right CNC equipment not only enhances operational capabilities but also contributes to overall cost savings, improved product quality, and reduced lead times. As manufacturers seek to navigate the complexities of modern production requirements, understanding the diverse range of CNC equipment available becomes essential for tailoring solutions that align with specific manufacturing needs. This comprehensive guide aims to elucidate the key factors to consider when choosing CNC equipment, ensuring businesses are well-equipped to meet current and future challenges in an increasingly automated world.

Identifying Your Specific Manufacturing Requirements for CNC Equipment

When selecting CNC equipment for your manufacturing operation, the first step is to clearly identify your specific manufacturing requirements. Factors such as the type of materials you'll be working with, the complexity of the parts to be machined, and the production volumes all play critical roles in determining the right CNC machinery for your needs.

According to a report by Technavio, the global CNC machine market is expected to grow by USD 5.64 billion from 2020 to 2024, highlighting the increasing demand for precision manufacturing across various industries.

When selecting CNC equipment for your manufacturing operation, the first step is to clearly identify your specific manufacturing requirements. Factors such as the type of materials you'll be working with, the complexity of the parts to be machined, and the production volumes all play critical roles in determining the right CNC machinery for your needs.

According to a report by Technavio, the global CNC machine market is expected to grow by USD 5.64 billion from 2020 to 2024, highlighting the increasing demand for precision manufacturing across various industries.

Another aspect to consider is the level of automation and sophistication required in your production process. For instance, if your business is focused on small-batch production with complex designs, investing in advanced CNC mills or multi-axis machines might be necessary. The 2022 World Machine Tool Survey indicates that the adoption of innovative CNC technology can significantly enhance productivity and reduce operational costs, making it essential to align your equipment choices with your operational goals. Additionally, evaluating your facility's available space and integration capabilities with existing machinery is crucial to ensure a seamless transition and optimal workflow.

Understanding Different Types of CNC Machines and Their Applications

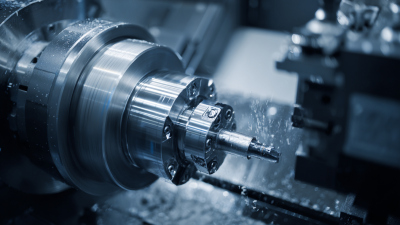

When selecting CNC equipment for your manufacturing operations, it's essential to understand the different types of CNC machines available and their specific applications. CNC milling machines are among the most versatile, offering the ability to create intricate parts from various materials, including metals and plastics. According to recent industry reports, CNC milling machines can achieve precision tolerances within 0.001 inches, making them ideal for sectors that demand high accuracy, such as aerospace and medical device manufacturing.

In addition to milling, CNC lathes play a crucial role in manufacturing by enabling the creation of cylindrical parts with a high surface finish. Data from the latest analysis indicates that lathe operations can significantly reduce production time, often achieving cycle times 50% faster than conventional methods. Furthermore, CNC routers are increasingly utilized in woodworking and composite materials, indicating a broader range of applications for CNC technology in diverse industries. Understanding these differences allows manufacturers to make informed decisions that align with their specific production needs.

How to Choose the Right CNC Equipment for Your Manufacturing Needs

This bar chart illustrates the various types of CNC machines and their common applications in the manufacturing industry.

Evaluating Key Features and Specifications of CNC Equipment

When selecting CNC equipment for manufacturing needs, it’s crucial to focus on key features and specifications that align with production requirements. Fundamental characteristics like precision, speed, and the capability to handle diverse materials are pivotal for ensuring optimal performance. For instance, the latest coil-winding machines highlight efficiency in producing coils essential for various electronic applications. These machines showcase innovations in automation that not only enhance productivity but also reduce labor costs, reflecting the ongoing trend in manufacturing that leverages advanced technologies.

Additionally, evaluating the technology integration in CNC equipment is important. The ability to utilize software for programming, monitoring, and remote operation can significantly impact the overall workflow and output quality. Recent discussions on the impact of automation on the labor market underscore the necessity of acquiring machines that bring about efficiencies without compromising on job safety and quality. Thus, when choosing CNC equipment, manufacturers should carefully assess these features to ensure they meet both current demands and future advancements in technology.

Budgeting for Your CNC Equipment Acquisition: Costs and Considerations

When budgeting for CNC equipment acquisition, it's crucial to consider the total cost of ownership beyond just the initial purchase price. This encompasses maintenance, tooling, and operating costs, which can significantly impact your overall investment. For instance, while a high-end CNC machine may have a steep upfront cost, its reliability and efficiency could lead to lower operational costs in the long run. It's essential to conduct a thorough analysis of your projected production volume and the specific functionalities you require to determine the most economically viable option.

Additionally, don’t overlook the implications of software and training costs, which are integral to maximizing the benefits of CNC technology. Upgrading software or acquiring industry-specific programs may add to your initial budget, but they can enhance machine performance and precision. Moreover, investing in training your staff to operate and maintain the equipment effectively can prevent costly mistakes and downtime. Balancing these costs with your manufacturing goals will ensure you choose CNC equipment that meets your needs while staying within your financial limits.

Researching and Comparing CNC Equipment Suppliers and Brands

When selecting the right CNC equipment for your manufacturing needs, researching and comparing suppliers and brands is crucial. According to a recent industry analysis from Mordor Intelligence, the global CNC machine market is expected to reach $100 billion by 2026, underscoring the growing demand for advanced technology in manufacturing. This rapid growth emphasizes the importance of identifying reliable suppliers who can provide high-quality, precision-driven CNC machines tailored to specific applications.

One effective approach is to create a shortlist of reputable CNC equipment manufacturers. Factors to consider include the company's history, customer reviews, and their service offerings. For instance, a J.D. Power study indicates that customer satisfaction plays a significant role in brand loyalty, with 78% of satisfied customers likely to repurchase. Furthermore, look for suppliers that provide comprehensive support and training programs, which can significantly enhance operational efficiency. Engaging with industry forums and trade shows can also provide valuable insights into the best-performing brands, ensuring that your investment aligns with industry standards and innovation trends.

How to Choose the Right CNC Equipment for Your Manufacturing Needs

| Specification | Details | Comparison Criteria |

|---|---|---|

| Type of CNC Machine | CNC Mill, CNC Lathe, CNC Router | Purpose of Use |

| Axis Configuration | 3-axis, 4-axis, 5-axis | Complexity of Parts |

| Maximum Spindle Speed | 5000 - 24000 RPM | Material Compatibility |

| Tooling System | Tool Changer, Manual Tooling | Efficiency Needs |

| Work Envelope Size | Small, Medium, Large | Part Size |

| Price Range | $5,000 - $150,000+ | Budget Constraints |

| Precision | 0.005 mm - 0.1 mm | Quality Requirements |

| Supplier Support | Warranty, Training, Maintenance | After-Sales Service |

Related Posts

-

The Ultimate Guide to Sourcing the Best CNC Machine Tools for Your Business Needs

-

The Ultimate Guide to Discovering Top Quality Suppliers for Best CNC Equipment

-

Maximizing Efficiency with the Best Cnc Machining Centers in Modern Manufacturing

-

Common Issues Facing the CNC Equipment Industry and Their Impact on Production Efficiency

-

5 Reasons Why Best CNC Manufacturing Leads to Exceptional Product Quality

-

Challenges Related to Best High Precision Cnc Machining Process Efficiency