A Comprehensive Comparison of Machining Costs Across Different Industries and Technologies

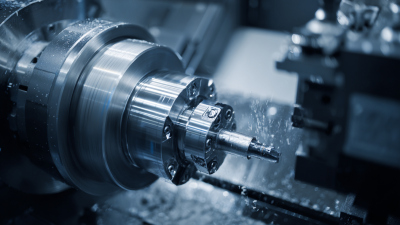

In today's manufacturing landscape, understanding "Machining Costs" is crucial for businesses aiming to optimize their production processes and enhance profitability. According to a recent report by Grand View Research, the global CNC machining market is expected to reach $100 billion by 2027, highlighting the increasing reliance on advanced machining technologies. Various industries, from Aerospace to Automotive, experience distinct cost structures influenced by factors such as material types, machine downtime, and labor expenses.

For instance, the aerospace sector often faces higher machining costs due to stringent quality control standards and complicated geometries, while the automotive industry benefits from high-volume production efficiencies. This comprehensive comparison will explore the nuances of machining costs across different industries and technologies, helping manufacturers make informed decisions that drive operational excellence and competitive advantage.

Overview of Machining Costs in Key Industries

In today's competitive landscape, machining costs have become a focal point of attention across various industries. The intricate relationship between lean management and advanced manufacturing techniques—such as additive manufacturing—highlights the efforts to optimize production processes while controlling costs. Industries that have embraced lean practices are witnessing significant transformations, becoming more efficient and resilient against the backdrop of rising expenditures. A comprehensive examination reveals that manufacturing sectors, particularly in the U.S., are grappling with escalating costs, influenced by factors such as tariffs and supply chain disruptions.

Key industries, including automotive and aerospace, are evaluated for their machining cost structures, showcasing distinct challenges and opportunities tied to technological advancements. The manufacturing ecosystem's ability to innovate is crucial for maintaining a competitive edge, especially against economic influences like fluctuating commodity prices. As firms navigate the pressures of higher operational costs, the need for investment in modern technologies becomes apparent, driving a shift towards productivity-enhancing strategies.

A Comprehensive Comparison of Machining Costs Across Different Industries and Technologies

| Industry | Machining Technology | Average Cost per Hour (USD) | Material Type | Typical Lead Time (Days) |

|---|---|---|---|---|

| Aerospace | CNC Machining | 150 | Aluminum Alloys | 30 |

| Automotive | Turning | 100 | Steel | 15 |

| Medical Devices | EDM | 200 | Titanium | 20 |

| Electronics | Laser Cutting | 120 | Copper | 10 |

| Construction | Milling | 90 | Concrete | 25 |

Comparative Analysis of Machining Technologies and Their Expenses

In today's rapidly evolving manufacturing landscape, understanding the expenses associated with different machining technologies is essential for businesses striving for cost-efficiency and competitive advantage. A recent report by MarketsandMarkets indicates that the CNC machining market is projected to grow from $69.8 billion in 2020 to $82.2 billion by 2026, highlighting the increasing investment in advanced machining technologies across various industries. Each technology, from traditional milling and turning to more sophisticated methods like additive manufacturing, carries its unique cost structure that companies must analyze to maximize their margins.

For instance, while conventional machining might offer lower initial expenses, its operational costs can rise substantially due to longer production times and increased waste. In contrast, additive manufacturing, though initially more expensive, can significantly reduce material costs and lead times, making it a viable option for industries such as aerospace and medical device manufacturing where precision is paramount.

Tip: When evaluating machining technologies, consider not only the upfront costs but also the long-term implications on production efficiency and material usage. A comprehensive understanding of your specific industry needs will allow you to make more informed decisions.

Moreover, the choice of technology should align with the specific characteristics of the materials being processed. A study by Grand View Research suggests that industries utilizing metals will increasingly adopt laser and waterjet cutting technologies for their ability to provide clean cuts and minimal heat-affected zones, ultimately resulting in lower post-processing costs.

Tip: Regularly reassessing your machining strategy against current industry trends can help ensure that your processes remain both cost-effective and technologically relevant.

Factors Influencing Machining Costs: A Detailed Examination

Machining costs are significantly influenced by a variety of factors including material type, complexity of design, and the technology employed. According to a report by the National Institute of Standards and Technology, these costs can vary widely among different industries, with aerospace machining costing up to 30% more than similar operations in the automotive sector due to stringent quality control and advanced materials used. Additionally, the choice between traditional machining and newer technologies like CNC machining can impact expenses; CNC machining, while initially more expensive due to setup costs, can lead to savings in scale and reduced labor costs over time.

Tips: When calculating machining costs, consider the total lifecycle of the project rather than just upfront costs. For instance, investing in more precise machinery may incur higher initial expenses but can result in significant savings through reduced waste and rework. Furthermore, keeping track of market trends and advancements in technology can help industries adapt quickly, thereby optimizing machining processes and costs. Regularly reviewing supplier performance and material costs can also yield opportunities for cost reduction. By understanding these influencing factors, businesses can make informed decisions and strategically manage their machining expenses.

Cost-Saving Strategies for Different Machining Processes

In today's competitive manufacturing landscape, understanding cost-saving strategies for various machining processes is essential. Each industry has unique challenges, but several universal tips can help streamline operations and reduce expenses. One effective strategy is optimizing tool selection. By using high-quality, durable tools designed for specific materials, manufacturers can enhance performance and longevity, ultimately lowering costs associated with tool replacements and maintenance.

Another important consideration is the adoption of advanced technologies like CNC machining or additive manufacturing. These methods often lead to reduced waste and increased precision, which can translate into significant cost savings. Investing in training for operators to fully utilize these technologies can also yield better production rates and quality, mitigating the risk of costly errors.

Additionally, consider implementing lean manufacturing principles to identify and eliminate waste in machining workflows. Regularly analyzing each step of the process can reveal inefficiencies that, once addressed, contribute to lower machining costs and improved overall productivity. Emphasizing continuous improvement across all stages of machining will not only conserve resources but also drive sustainable growth for the business.

Future Trends in Machining Costs: Insights and Predictions

As manufacturing technologies continue to evolve, the landscape of machining costs is set to transform significantly in the coming years. Advancements in automation and the integration of artificial intelligence into machining processes are anticipated to streamline operations, resulting in lower overhead costs. Industries that embrace these technologies can expect enhanced precision and shorter production times, ultimately leading to a reduction in machining costs. This shift not only benefits manufacturers by improving profit margins but also makes competitive pricing more attainable for smaller players in the market.

Additionally, the rising trend of sustainable manufacturing practices is influencing machining costs. Companies are increasingly focused on minimizing waste and optimizing materials, which can initially require higher investments in cutting-edge machinery. However, the long-term benefits, such as reduced material costs and energy savings, are expected to offset these expenses. Furthermore, consumer demand for eco-friendly products is pushing manufacturers to adopt greener technologies, which could drive further innovations and cost efficiencies in machining processes. The next few years will likely showcase a dynamic interplay between technology advancements and sustainability initiatives, shaping the future of machining costs across various industries.

A Comprehensive Comparison of Machining Costs Across Different Industries

Related Posts

-

Ultimate Checklist for Sourcing the Best Precision Tools: Key Metrics and Supplier Insights

-

Challenges Related to Best High Precision Cnc Machining Process Efficiency

-

7 Essential Benefits of Best Cnc Machining Precision in Modern Manufacturing

-

How to Choose the Best Precision Manufacturing Partner for Your Global Supply Chain

-

Maximizing Efficiency with the Best Cnc Machining Centers in Modern Manufacturing

-

Essential Techniques for Optimizing CNC Manufacturing Efficiency in Your Factory