5 Essential Tips for Choosing the Best CNC Machining Parts

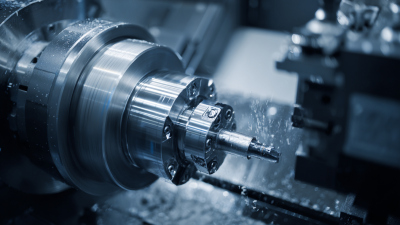

In the fast-evolving landscape of manufacturing, the significance of high-quality CNC machining parts cannot be overstated. According to a report by Allied Market Research, the global CNC machining market is projected to reach $100 billion by 2025, driven by the increasing demand for precision-engineered components across various industries, from aerospace to automotive. With the rise of advanced technologies, the complexity and customizability of CNC machining parts have also escalated, making it crucial for manufacturers and engineers to choose the right parts meticulously. This choice can significantly impact efficiency, product quality, and overall operational success. Therefore, understanding the essential factors to consider when selecting CNC machining parts is key to navigating this competitive market effectively.

Understanding the Common Issues in CNC Machining Parts Selection

When selecting CNC machining parts, understanding common issues can significantly enhance your decision-making process. One prevalent challenge is ensuring the right material is chosen for your specific application. Different materials exhibit varying levels of strength, durability, and resistance to heat or corrosion. Familiarizing yourself with these characteristics helps avoid costly mistakes and ensures the longevity of the parts.

Another critical consideration is the tolerance levels required for your project. CNC machining allows for high precision, but not every project may demand the same accuracy. A common issue arises when parts are over-engineered, leading to unnecessary complexity and cost. It’s essential to clarify the tolerances and specifications needed early in the selection process to streamline manufacturing and maintain budget constraints. Addressing these common issues can lead to more effective CNC parts selection and improved project outcomes.

Key Factors to Consider When Choosing CNC Machining Materials

When selecting the best CNC machining materials, understanding key factors is crucial for achieving optimal results. CNC (Computer Numerical Control) machining relies heavily on the choice of materials, as they directly influence the performance, durability, and overall quality of the finished parts. One of the primary considerations is the material's machinability—properties such as hardness, corrosion resistance, and thermal stability significantly affect how easily a material can be processed and shaped. For instance,

aluminum is favored for its lightweight and excellent machinability, while stainless steel is often chosen for its strength and resistance to rust.

Another essential factor is the application's specific requirements, which may dictate the choice of materials. For industries like aerospace and automotive, where performance is paramount, advanced alloys or composites may be necessary to withstand extreme conditions.

According to recent market analysis, the CNC machine market is projected to expand significantly, from $101.22 billion in 2025 to $195.59 billion by 2032, with a compound annual growth rate of 9.9%. This growth underscores the increasing importance of high-quality machining materials and the need for careful material selection in order to meet evolving industry demands and standards.

The Importance of Precision and Tolerance in CNC Parts

When it comes to CNC machining, precision and tolerance are paramount. These factors determine the overall quality and functionality of the machined parts.

Precision refers to the degree of exactness in the dimensions of the machined component. Ensuring high precision means that parts fit together seamlessly, which is crucial for complex assemblies found in industries such as aerospace, automotive, and medical devices. A slight deviation in measurements can lead to significant functional issues, making precision a critical consideration when selecting CNC parts.

Precision refers to the degree of exactness in the dimensions of the machined component. Ensuring high precision means that parts fit together seamlessly, which is crucial for complex assemblies found in industries such as aerospace, automotive, and medical devices. A slight deviation in measurements can lead to significant functional issues, making precision a critical consideration when selecting CNC parts.

Tolerance, on the other hand, defines the allowable variation in dimensions. It is essential for ensuring that parts can be manufactured consistently without compromising performance. Tight tolerances are often required for high-performance applications, where even the smallest imperfections can be detrimental. Understanding the specific tolerance requirements for your project helps in selecting the right machining process and materials, ensuring that the final product meets the desired quality standards. By prioritizing both precision and tolerance, manufacturers can produce CNC machined parts that not only meet specifications but also enhance the overall efficiency and reliability of the final assembly.

Evaluating Cost vs. Quality: Finding the Right Balance in CNC Machining

When it comes to CNC machining, balancing cost and quality is a critical factor that can significantly impact your project’s success. Lowering costs might tempt many buyers, but it's essential to remember that skimping on quality can lead to long-term setbacks. Subpar machining parts may result in higher scrap rates, additional rework, and ultimately, delays in production that can affect the company's bottom line. Therefore, evaluating the trade-offs between cost and quality is crucial to making an informed decision.

A strategic approach involves defining your project's specific requirements beforehand. Consider the complexity of the parts, the material being used, and the tolerances needed. High-precision components may justify a higher price due to the stringent manufacturing processes required, while simpler parts might allow for cost-saving options without compromising quality. Additionally, supplier reputation plays an essential role; investing time in sourcing reliable partners can lead to substantial savings over time by minimizing the risks of defects and failures in the final product. By carefully assessing these factors, you can achieve an optimal balance that meets both your financial constraints and quality expectations.

Essential Questions to Ask Your CNC Machining Supplier Before Committing

When selecting a CNC machining supplier, asking the right questions is crucial to ensure the quality and reliability of your parts. Start by inquiring about their experience and expertise in the specific materials you need. Understanding their proficiency in working with metals, plastics, or composites will give you confidence in their capabilities to meet your project requirements. Additionally, ask them about the types of CNC machines they employ and the technologies they utilize, as this can significantly impact the precision and finish of your final product.

Another essential question involves their quality control processes. Find out how they ensure that each part meets your specifications and industry standards. A supplier should have robust testing and inspection protocols in place. Furthermore, inquire about their lead times and flexibility in production schedules. This information will help you gauge whether they can accommodate your project's timelines and adapt to any changes that may arise. By asking these critical questions, you can build a strong partnership with your CNC machining supplier and secure high-quality components for your projects.

Related Posts

-

Real-World Applications of Best CNC Machining: How Precision Manufacturing Transforms the Aerospace Industry

-

7 Essential Benefits of Best Cnc Machining Precision in Modern Manufacturing

-

Exploring the Unique Features and Applications of Diverse Cnc Machining Alternatives for Global Buyers

-

5 Reasons Why Best CNC Manufacturing Leads to Exceptional Product Quality

-

Maximizing Efficiency with the Best Cnc Machining Centers in Modern Manufacturing

-

Essential Techniques for Optimizing CNC Manufacturing Efficiency in Your Factory