Global CNC Milling Trends: 2025 Market Insights and Future Opportunities

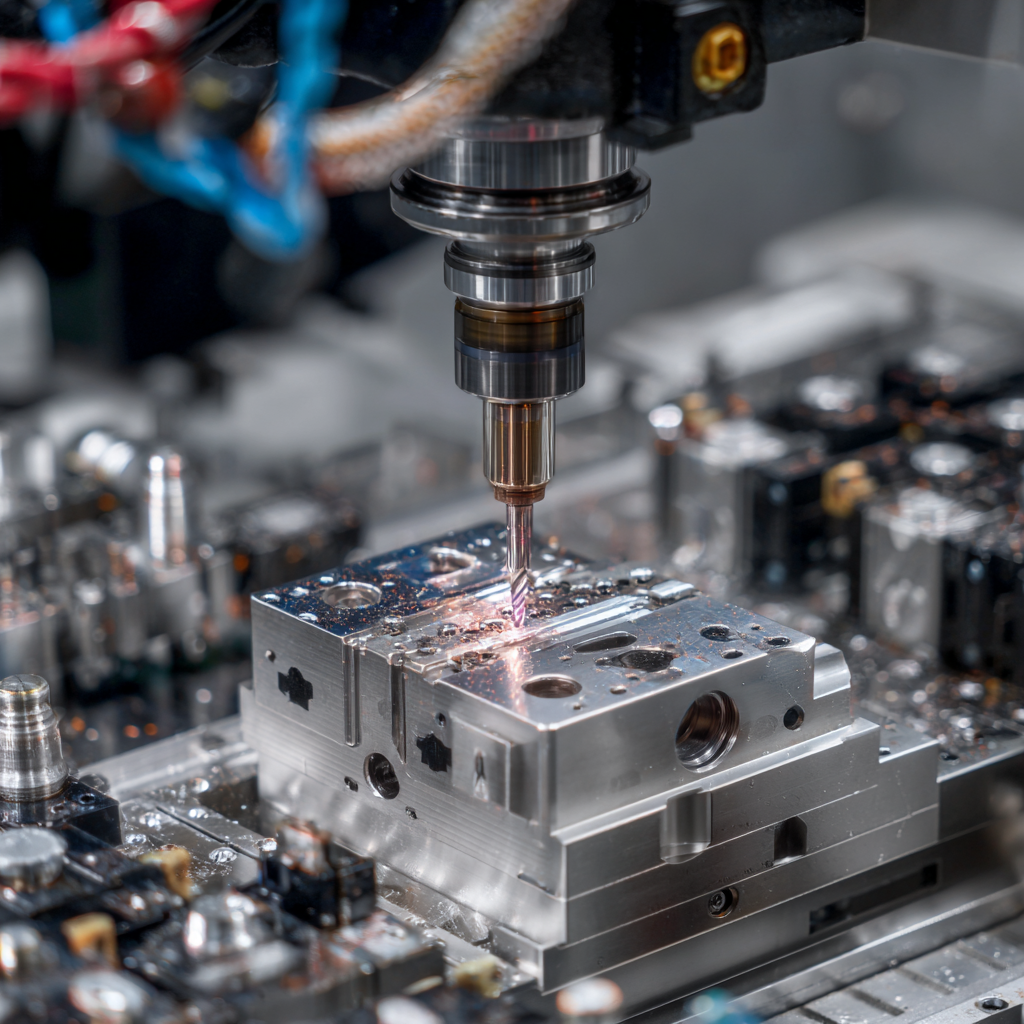

As we approach 2025, the CNC milling industry is witnessing transformative trends that are reshaping market dynamics and opening new avenues for growth. According to a recent report by MarketsandMarkets, the global CNC milling market is anticipated to grow from USD 10.39 billion in 2020 to USD 14.57 billion by 2025, reflecting a robust compound annual growth rate (CAGR) of 6.8%. This growth is fueled by advancements in automation, increased demand for precision machining, and the rising need for customized solutions across various sectors, including aerospace, automotive, and medical devices. Furthermore, the integration of Industry 4.0 technologies is enabling manufacturers to enhance productivity and efficiency, positioning CNC milling as a critical component in the future of manufacturing. As we explore the key trends and future opportunities in this blog, we will provide a comprehensive checklist to equip industry stakeholders with the insights necessary to navigate the evolving landscape of CNC milling.

Current State of the Global CNC Milling Market: Key Statistics and Insights

The global CNC milling market is currently experiencing significant transformation driven by advancements in technology and increasing demand across various industries. As of 2023, the CNC milling machine market is valued at approximately $XX billion, with an impressive CAGR of XX% projected over the next few years. This growth is fueled by sectors such as automotive, aerospace, and healthcare, where precision and efficiency are critical. Companies are increasingly adopting CNC milling for production, driven by the need for high-quality outputs with minimal waste.

Moreover, the integration of automation and smart technology into CNC milling processes is reshaping market dynamics. Companies are leveraging IoT and AI to enhance operational efficiency, allowing for real-time monitoring and predictive maintenance, which reduces downtime and improves overall productivity. Additionally, the ongoing push towards sustainable manufacturing practices is encouraging businesses to invest in energy-efficient CNC milling solutions. As the market evolves, stakeholders must stay informed on these key trends to capitalize on emerging opportunities and maintain a competitive edge in the global landscape.

Global CNC Milling Trends: 2025 Market Insights and Future Opportunities

| Market Segment | 2023 Market Size (USD Billion) | CAGR 2023-2025 (%) | Projected Market Size 2025 (USD Billion) | Key Growth Drivers |

|---|---|---|---|---|

| Aerospace | 5.4 | 6.5 | 7.0 | Innovation in Aircraft Design |

| Automotive | 10.2 | 4.2 | 11.1 | Rise in Electric Vehicle Production |

| Medical Devices | 3.1 | 7.8 | 3.8 | Growing Demand for Customized Solutions |

| Electronics | 7.5 | 5.1 | 8.6 | Technological Advancements in Micro-manufacturing |

| Energy Sector | 2.8 | 6.0 | 3.5 | Focus on Renewable Energy Solutions |

Emerging Technologies Shaping CNC Milling: Trends to Watch in 2025

As we approach 2025, several emerging technologies are poised to reshape the CNC milling landscape, offering exciting opportunities for manufacturers. One of the most significant trends is the increasing integration of robotic technology, which is enhancing automation capabilities throughout the CNC milling process. This development not only improves efficiency but also allows for greater precision and flexibility in production, enabling manufacturers to meet diverse customer demands more effectively.

Another critical trend to watch is the rise of advanced CNC machining centers, particularly vertical machining centers. Projected growth in this market underlines the shift towards more sophisticated and versatile machinery that can handle a wider variety of materials and complex designs. As manufacturers invest in these technologies, they are likely to see substantial returns and an expansion of their market share.

Embracing these emerging technologies will be essential for businesses looking to capitalize on the growing CNC milling sector in the coming years.

Impact of Industry 4.0 on CNC Milling Efficiency and Automation

In the rapidly evolving landscape of CNC milling, the integration of Industry 4.0 technologies is driving significant advancements in efficiency and automation. As the global machine tools market is projected to grow from USD 97.1 billion in 2024 to USD 196 billion by 2034, reflecting a CAGR of 7.5% from 2025, manufacturers are increasingly embracing smart technologies to enhance their operational capabilities. The infusion of Internet of Things (IoT) devices, big data analytics, and AI into CNC processes has resulted in improved precision, reduced downtime, and streamlined workflows.

Artificial intelligence is at the forefront of this transformation, reshaping the future of precision manufacturing. By leveraging predictive maintenance, automated programming, and adaptive machining techniques, companies can optimize their CNC milling operations for higher productivity and accuracy. The use of AI enables manufacturers to anticipate machine failures before they occur, minimizing production disruptions and costs associated with unplanned downtimes. As these technologies continue to develop, we can expect a significant shift in how CNC milling is performed, setting new benchmarks for efficiency and quality in the manufacturing sector.

Artificial intelligence is at the forefront of this transformation, reshaping the future of precision manufacturing. By leveraging predictive maintenance, automated programming, and adaptive machining techniques, companies can optimize their CNC milling operations for higher productivity and accuracy. The use of AI enables manufacturers to anticipate machine failures before they occur, minimizing production disruptions and costs associated with unplanned downtimes. As these technologies continue to develop, we can expect a significant shift in how CNC milling is performed, setting new benchmarks for efficiency and quality in the manufacturing sector.

Sustainability Practices in CNC Milling: Opportunities for Eco-Friendly Innovation

As the CNC milling industry continues to evolve, sustainability practices are emerging as a key focus area. Manufacturers are increasingly recognizing the need to minimize their environmental footprint while maintaining operational efficiency. This shift towards eco-friendly innovation opens up a plethora of opportunities for businesses willing to adapt. From using biodegradable cutting fluids to implementing energy-efficient machinery, the CNC milling sector is poised to lead the charge toward greener manufacturing practices.

Moreover, advancements in recycling technologies are paving the way for the reprocessing of materials that were previously discarded. By adopting closed-loop systems that allow for the reuse of metal shavings and waste, companies can significantly reduce material costs while contributing to a circular economy. This not only enhances sustainability but also aligns with the growing consumer demand for environmentally responsible products. As businesses prioritize eco-friendly methods, they are not only improving their brand image but are also positioning themselves favorably in an increasingly competitive market.

Global CNC Milling Trends: 2025 Market Insights

This chart illustrates the projected growth of the CNC milling market, highlighting the increasing market size and the rising opportunities in eco-friendly innovation from 2021 to 2025. The data indicates a robust trend towards sustainability practices in the CNC milling sector.

Future Market Opportunities: Target Sectors for CNC Milling Growth by 2025

The CNC milling industry is poised for significant growth as we approach 2025, with several sectors emerging as key targets for expansion. According to recent market analyses, the demand for CNC machine tools is anticipated to soar, contributing an impressive $21.9 billion in market growth from 2025 to 2029. This increase is largely driven by the rising need for high-precision and multi-axis machining centers, showcasing the industry's evolution propelled by advancements in artificial intelligence.

Another promising sector lies within the industrial manufacturing landscape, where the global machine tools industry is projected to reach $105.11 billion by 2032, up from $81.09 billion in 2025. This growth aligns with the ongoing industrialization efforts and infrastructure development globally, indicating robust opportunities for CNC milling processes. Furthermore, the surge in the renewable energy sector and automotive manufacturing activities further bolsters the demand for sophisticated CNC milling applications, creating a vibrant environment for innovation and investment in this field.