Real-World Applications of Best CNC Machining: How Precision Manufacturing Transforms the Aerospace Industry

In recent years, the aerospace industry has witnessed a remarkable transformation driven by advancements in CNC machining technologies. According to a report by Markets and Markets, the global aerospace CNC machining market is projected to reach USD 8.2 billion by 2025, growing at a CAGR of 5.9% from 2020. This surge is primarily attributed to the increasing demand for precision components that meet stringent safety and performance standards in aviation. CNC machining not only enhances the accuracy and efficiency of manufacturing processes but also allows for the production of complex geometries that are essential for modern aircraft design.

As companies in China position themselves to export their world-class manufacturing capabilities globally, the implementation of cutting-edge CNC machining techniques stands at the forefront of this evolution, reinforcing the nation's commitment to innovation and excellence in the aerospace sector.

Real-World Impact of CNC Machining on Aerospace Component Precision

The impact of CNC machining on the aerospace industry cannot be overstated, particularly when it comes to component precision. According to a report by Markets and Markets, the aerospace CNC machining market is projected to grow from $2.2 billion in 2021 to $3.8 billion by 2026, reflecting a CAGR of 11.2%. This growth can be attributed to the increasing demand for lightweight and high-strength materials in aircraft manufacturing, where even minute variances can lead to performance and safety issues.

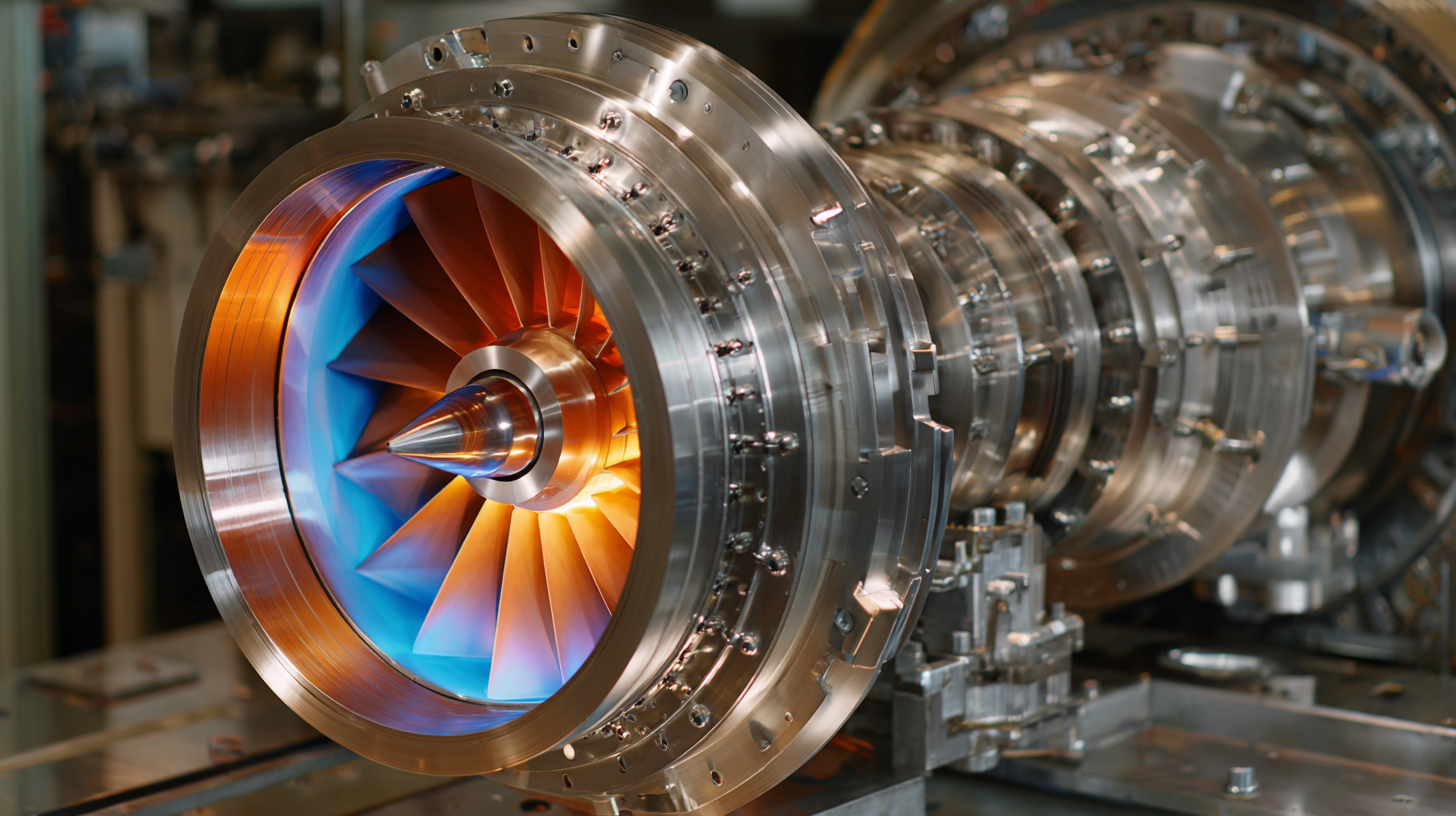

CNC machining allows for the production of complex geometries that are both precise and repeatable. The ability to operate with tolerances as tight as ±0.001 inches enhances the reliability of critical aerospace components, such as turbine blades and structural frames. A case study conducted by Boeing revealed that the integration of CNC technology into their production line reduced part rejection rates by 27%, significantly cutting costs and lead times. With aerospace manufacturers continuously adopting advanced CNC machining techniques, the industry is well-positioned to meet the rigorous standards of design and safety while driving innovation.

Real-World Applications of Best CNC Machining: How Precision Manufacturing Transforms the Aerospace Industry

| Component Type | Material Used | Precision Tolerance (mm) | Production Volume (units/year) | Application Area |

|---|---|---|---|---|

| Wing Structure | Aluminum Alloy | 0.01 | 500 | Commercial Aviation |

| Engine Components | Titanium Alloy | 0.005 | 200 | Military Aviation |

| Fuel System Parts | Stainless Steel | 0.02 | 300 | Commercial Aviation |

| Landing Gear | Carbon Fiber Composite | 0.03 | 150 | Commercial Aviation |

| Braking Systems | Aluminum and Composite | 0.01 | 250 | Military Aviation |

Advancements in CNC Technologies Driving Aerospace Innovations

Advancements in CNC technologies are driving significant innovations within the aerospace industry. The global CNC controller market, valued at $3.2 billion in 2023, is projected to reach $7.2 billion by 2033, reflecting a robust CAGR of 8.3% from 2024 onwards. This growth highlights the increasing reliance on precision manufacturing processes that CNC machining facilitates, enabling aerospace companies to produce complex components with exceptional accuracy and efficiency.

Moreover, the CNC machine market is expected to witness a CAGR of 5.5%, potentially exceeding $123 billion by 2034. This expansion is fueled by the demand for enhanced automation and productivity in smart manufacturing environments. The incorporation of emerging technologies such as AI, robotics, and additive manufacturing not only optimizes production capabilities but also transforms traditional tooling approaches in aerospace and defense. These innovations are set to reshape how aerospace manufacturers deliver advanced solutions, ultimately contributing to the industry's evolution and competitiveness on a global scale.

Impact of CNC Machining Technologies on Aerospace Manufacturing

This chart illustrates the advancements in CNC machining technologies and their impact on productivity, precision, and cost savings in the aerospace industry over the last five years.

Quality Assurance in CNC Machining: Ensuring Safety in Aerospace

Ensuring safety in the aerospace industry is paramount, and quality assurance in CNC machining is vital to achieving this goal. Reports from the Aerospace Industries Association indicate that precision manufacturing leads to a reduction in assembly-related defects by up to 30%. This reduction is critical in aerospace, where even the smallest imperfections can lead to catastrophic failures during flight. Implementing rigorous quality assurance protocols throughout the CNC machining process guarantees that components meet stringent industry standards, fostering both reliability and safety in aircraft design and manufacturing.

Tip: Implement regular audits and inspections of CNC machining processes to identify and address potential quality issues before they escalate. Use statistical process control (SPC) techniques to monitor production consistency and maintain high standards.

Additionally, the integration of advanced technologies such as automated inspection systems within CNC machining enhances quality assurance measures. These systems can evaluate part accuracy in real-time, ensuring that every dimension adheres to predetermined specifications. According to a recent study, organizations that adopted automated inspection have experienced a 50% increase in productivity, significantly impacting overall safety and performance in the aerospace sector.

Tip: Invest in training for CNC machinists on the latest inspection technologies to optimize quality control processes, thereby reinforcing the safety of aerospace applications.

Collaborative Opportunities Between Chinese Manufacturers and Aerospace Firms

The aerospace industry has always been at the forefront of technological innovation, and the integration of CNC machining into manufacturing processes is revolutionizing how companies approach production. Chinese manufacturers, renowned for their precision and efficiency, are establishing collaborative relationships with aerospace firms worldwide. This partnership opens up a myriad of opportunities, allowing for the blend of advanced machining techniques and cutting-edge aerospace designs.

These collaborations are not merely transactional; they foster a rich exchange of knowledge and expertise. By leveraging China's robust CNC machining capabilities, aerospace companies can enhance their production lines, reduce lead times, and improve overall product quality. Chinese manufacturers are adept at producing complex components that meet stringent aerospace standards, making them valuable partners for firms looking to innovate. As these alliances grow, they pave the way for the creation of lighter, more fuel-efficient aircraft that align with the industry's push for sustainability.

Additionally, with the rise of digital technologies and Industry 4.0, these collaborative ventures are more efficient than ever. Data sharing and real-time communication between Chinese manufacturers and aerospace companies enable a seamless workflow, ensuring that precision machining translates into superior end products. As both sides work together, they not only improve manufacturing processes but also solidify a competitive edge in an increasingly globalized market.

Case Studies: Successful Applications of CNC Machining in Aerospace Projects

CNC machining has revolutionized the aerospace industry, offering precision and efficiency that are essential for manufacturing complex components. The successful application of CNC technologies in aerospace projects exemplifies this transformation. For instance, companies have leveraged advanced CNC processes to produce lightweight components that are both strong and durable. By utilizing high-performance materials tailored for specific applications, these organizations ensure that their products meet stringent industry standards while optimizing performance.

Recent case studies highlight the integration of additive manufacturing and CNC machining in aerospace, leading to remarkable innovations. Notable projects showcase the development of intricate geometries that were previously unattainable with traditional manufacturing methods. The synergy between CNC machining and additive techniques not only enhances the design possibilities but also significantly reduces waste and production time. As aerospace firms continue to adopt these advanced manufacturing strategies, their ability to meet the rising demands for sustainable and efficient production will shape the future of aviation technology.