What Are Stainless Hex Nuts and How Are They Used?

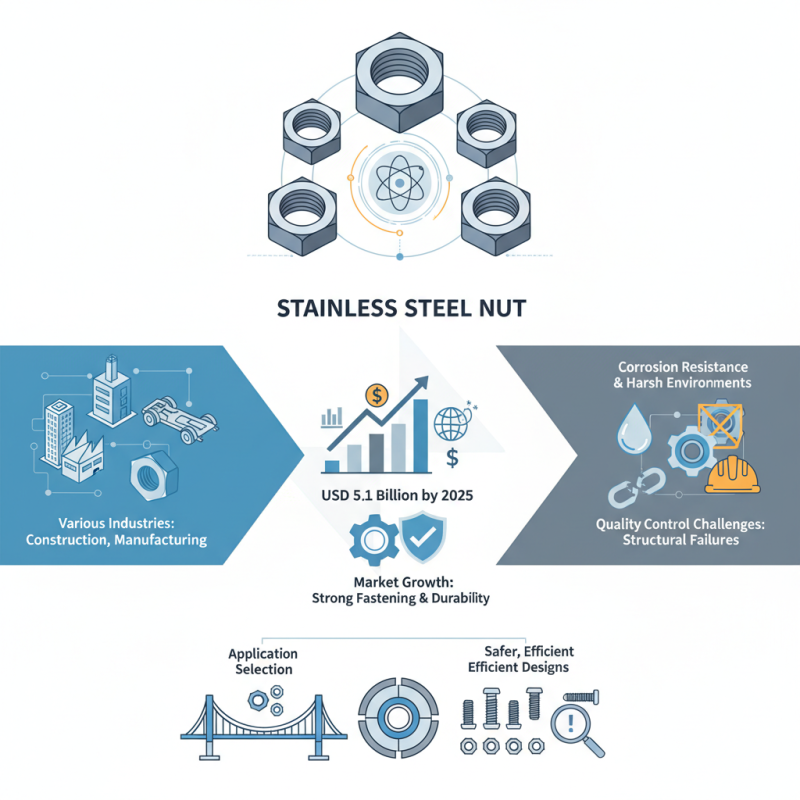

Stainless Hex Nuts are essential components in various industries. They are widely used in construction, automotive, and manufacturing sectors. According to a recent market report by Grand View Research, the global hex nut market is projected to grow significantly, reaching USD 5.1 billion by 2025. This growth underscores the importance of these seemingly simple fasteners.

These nuts provide a strong fastening solution, often used with bolts in assemblies. They are favored for their corrosion resistance and durability. Manufacturers prefer Stainless Hex Nuts due to their ability to withstand harsh environments. However, there are challenges, such as ensuring quality control during production. Inadequate quality can lead to structural failures, affecting safety and performance.

While Stainless Hex Nuts seem straightforward, their applications are complex. From bridges to machinery, they play a vital role. Yet, it’s crucial to remember that not all hex nuts are created equal. Choosing the right specifications for the intended application is vital. Regular assessments of these components can improve reliability. Understanding the nuances of Stainless Hex Nuts can lead to safer, more efficient designs in engineering.

What Are Stainless Hex Nuts? Definition and Key Characteristics

Stainless hex nuts are crucial fasteners in various industries. They are made from stainless steel, which provides excellent resistance to rust and corrosion. Their hexagonal shape allows for easy gripping and tightening. These nuts are used with bolts to create strong, durable connections.

One key characteristic of stainless hex nuts is their versatility. They can be found in construction, automotive, and machinery applications. Their strength makes them ideal for securing heavy loads. However, not all stainless steel is the same; different grades offer varied levels of strength and resistance. It is essential to choose the right grade for the specific application.

Sometimes, users overlook the importance of proper fit. A nut that is too loose can lead to failures. Conversely, one that is too tight may strip threads or break. To ensure reliability, it is vital to consider both compatibility and the environment in which the nut will be used. Choosing the right stainless hex nut can impact overall performance.

What Are Stainless Hex Nuts and How Are They Used?

| Characteristic | Description |

|---|---|

| Material | Stainless Steel (304, 316) |

| Shape | Hexagonal |

| Common Uses | Construction, Automotive, Machinery Assembly |

| Corrosion Resistance | High resistance to rust and acid |

| Sizes | Available from M2 to M30 and fractional sizes |

| Thread Type | Metric and Unified threads available |

| Standards | ASTM F593, ASME B18.2.2 |

Common Materials Used in Stainless Hex Nuts and Their Benefits

Stainless hex nuts are essential components in various applications. Their strength and resistance to corrosion make them ideal for challenging environments. The common materials used for manufacturing these nuts include austenitic stainless steel, ferritic stainless steel, and martensitic stainless steel. Each type offers unique benefits that cater to different needs.

Austenitic stainless steel, for instance, contains high levels of chromium and nickel. This combination provides excellent corrosion resistance and high-temperature strength. According to a report by the Stainless Steel Development Association, over 60% of stainless steel hex nuts are made from austenitic grades due to their versatility. On the other hand, ferritic stainless steel is magnetic and less ductile. It is often chosen for applications where magnetic properties are required.

While these materials are robust, they aren't perfect. Ferritic grades can suffer from stress corrosion cracking under certain conditions. This limitation necessitates careful selection based on environmental factors. Proper understanding and testing of conditions can enhance performance. In some cases, the use of martensitic stainless steel, known for its hardness, may lead to challenges during assembly. Balancing strength and ease of use is crucial for different projects.

Industrial Applications of Stainless Hex Nuts in Various Sectors

Stainless hex nuts serve a crucial role in various industrial applications. They provide secure fastening in machinery and structural components. The structural integrity hinges on these fasteners, especially in sectors like construction and automotive manufacturing. According to a report by the Global Fastener Market, the demand for stainless nuts is projected to grow by 5% annually due to rising construction projects.

In the aerospace industry, stainless hex nuts are vital. They withstand extreme temperatures and environmental conditions. Corrosion resistance is essential when securing critical aircraft components. The International Association of Machinists noted that over 70% of aircraft maintenance issues stem from fastener failures. This highlights the importance of using high-quality materials, like stainless steel, to prevent such failures.

However, not all applications may benefit from stainless hex nuts. Some environments require specialized fasteners that offer better performance. For example, in marine applications, even stainless fasteners can corrode under certain conditions. The industry needs to assess the suitability of stainless materials based on specific conditions. This ongoing evaluation of materials is crucial in ensuring longevity and safety in diverse applications.

Performance Metrics: Strength, Corrosion Resistance, and Longevity

Stainless hex nuts are popular fasteners in various industries. Their strength is one of the key performance metrics. They withstand significant torque and maintain their integrity under pressure. This makes them ideal for heavy-duty applications. The solid construction helps prevent failure in critical systems. However, not all stainless steel is equal. Some grades may not meet specific load requirements.

Corrosion resistance is another vital characteristic of stainless hex nuts. These nuts can withstand moisture and chemicals. They resist rusting and deterioration over time. This quality is crucial when used in outdoor environments or in contact with water. Yet, they can still be vulnerable under certain conditions. It is essential to evaluate the environment before choosing the right nut.

Longevity is promised, but there are factors to consider. Regular maintenance can prolong their lifespan. Over-tightening can cause wear and tear. It can also lead to threading issues. Users should not overlook these potential problems. Choosing the right application is crucial. Understanding these performance metrics can enhance longevity, ensuring reliable use in various situations.

Performance Metrics of Stainless Hex Nuts

Best Practices for Selecting and Installing Stainless Hex Nuts

Selecting the right stainless hex nuts for your project is crucial. Start by considering the materials you’ll be using. A mismatch can lead to corrosion or failure. Pay attention to the nut's grade. Higher grades offer better strength and corrosion resistance but may cost more. Always check specifications to ensure compatibility.

Installation is just as important as selection. Clean the surfaces where the nut will go. Dirt or rust can affect performance. Use a proper wrench for tightening. Over-tightening can strip threads or break parts. Many people overlook this, leading to issues later.

It’s wise to test a few nuts first. See how they perform under pressure. Some may not hold up as expected. Document these findings. This can help with future projects. Keeping track of what works—and what doesn’t—is vital. Adjusting your choices based on practical experience leads to better results.