Unlocking the Future of Manufacturing: How CNC Precision is Revolutionizing Industries

In recent years, CNC precision has emerged as a transformative force in the manufacturing landscape, driving unprecedented advancements across various industries. According to a report by Grand View Research, the global CNC machining market size was valued at approximately $63 billion in 2020 and is expected to expand at a compound annual growth rate (CAGR) of 6.2% from 2021 to 2028. This remarkable growth reflects the increasing demand for precision engineering, where CNC technology plays a pivotal role by enhancing accuracy and reducing waste. Furthermore, a survey conducted by the National Association of Manufacturers highlighted that 92% of manufacturers see improved productivity through the integration of CNC precision tools. As we delve into the future of manufacturing, it is clear that CNC precision not only streamlines operations but also paves the way for innovation, making it indispensable for industries aiming to thrive in a competitive marketplace.

The Evolution of CNC Technology in Modern Manufacturing

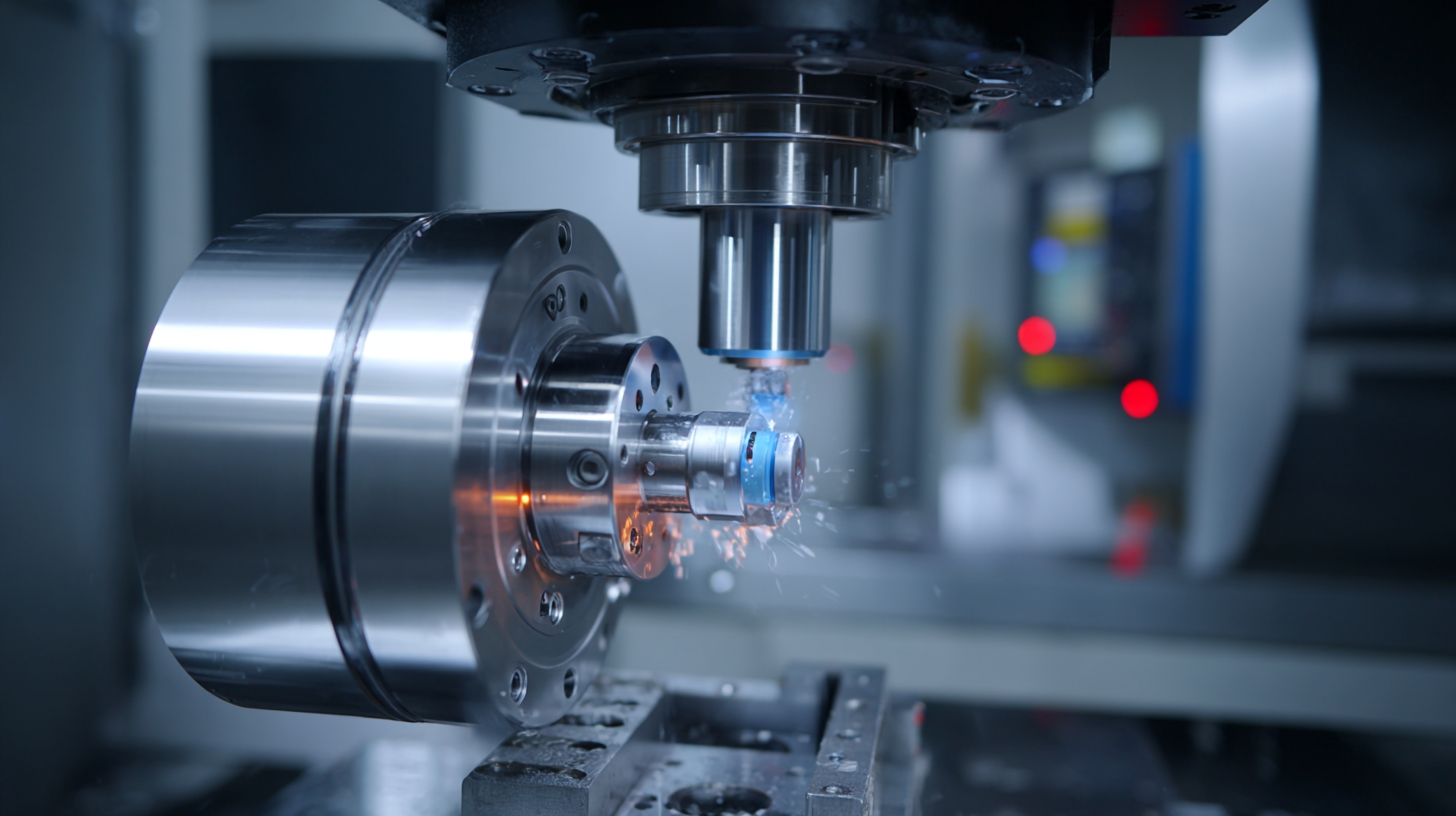

The evolution of CNC (Computer Numerical Control) technology has become a cornerstone in modern manufacturing, significantly enhancing the precision and efficiency of production processes. Advanced machine tools equipped with CNC capabilities allow for the intricate shaping and machining of materials, providing manufacturers with the ability to create highly detailed components with minimal human intervention. This technological shift has led to increased productivity across various industries, ensuring products meet exact specifications while maintaining consistency in quality.

As industries adopt new digital manufacturing technologies, CNC machining is evolving to incorporate smart systems that optimize operations. The integration of AI and robotics into CNC machinery is reshaping manufacturing landscapes, fostering an era where precision meets productivity. Companies are benefiting from these advancements by improving operational efficiencies, reducing waste, and addressing the skill gaps in the workforce through enhanced vocational training programs. These innovations not only cater to current market demands but also pave the way for continued growth in the CNC machine market, making it a pivotal element in the future of manufacturing.

Key Advantages of CNC Precision Over Traditional Methods

CNC precision machining represents a significant advancement over traditional manufacturing methods, primarily through its unmatched accuracy and consistency. Unlike manual machining, which can vary based on the operator's skill and experience, CNC machines are programmed to produce parts with extreme precision. This capability reduces the margin for error, ensuring that every component meets exact specifications, which is critical in industries such as aerospace and medical devices where tolerances are vital for safety and performance.

Additionally, CNC technology enhances efficiency in the production process. Automation allows for faster setup and higher throughput, significantly reducing production times. Traditional methods often involve lengthy manual operations, which can lead to bottlenecks and increased labor costs. With CNC systems, multiple tasks can be executed simultaneously, and once programmed, these machines can run unattended, optimizing factory operation hours. This shift towards automation not only streamlines production but also allows manufacturers to allocate resources more effectively, paving the way for innovation and scalability in the manufacturing sector.

Unlocking the Future of Manufacturing: Advantages of CNC Precision Over Traditional Methods

This chart illustrates the key advantages of CNC precision manufacturing compared to traditional manufacturing methods based on various factors such as accuracy, efficiency, flexibility, and waste reduction.

Impact of CNC on Industry Efficiency and Quality Control

The impact of CNC technology on industry efficiency and quality control cannot be overstated.

CNC machines significantly enhance precision and accuracy in manufacturing processes, allowing industries to produce intricate designs that were previously difficult or impossible to achieve. This technology minimizes human error and reduces waste, leading to increased profitability and sustainability in operations. As industries embrace CNC machines, they experience a shift towards automated, high-speed production capabilities that meet the growing demand for customized products.

Tip: When investing in CNC technology, consider not only the initial costs but also the long-term benefits of increased efficiency and product quality. By integrating CNC into your production line, you can streamline processes and ensure consistent results that exceed customer expectations.

Moreover, the evolving landscape of industrial automation highlights the necessity for organizations to adopt digital manufacturing techniques. With the rise in demand for automated solutions, companies are transitioning from traditional methods to advanced CNC systems. This adaptation not only enhances operational efficiency but also fosters innovation within the manufacturing sector.

Tip: Regular training for staff on CNC operations can further optimize your production processes, ensuring that your team is well-equipped to handle modern machinery and stay ahead in the competitive market.

Future Trends: Smart Manufacturing with CNC Integration

The integration of CNC (Computer Numerical Control) technology is driving a paradigm shift in smart manufacturing, facilitating higher precision and efficiency across diverse industries. With the global CNC machine market projected to grow from $13.26 billion in 2025 to $22.94 billion by 2032, reflecting a compound annual growth rate (CAGR) of 8.1%, the appetite for advanced manufacturing solutions is surging. This momentum is bolstered by innovations in dexterous robotic systems, as showcased by the research team led by Academician Ding Han and Professor Zhao Huan from Huazhong University of Science and Technology, emphasizing the transformative potential of automation in production lines.

Moreover, advancements in CNC controllers, forecasted to expand from approximately $33.67 million in 2025 to $22.87 million by 2033, illustrate the ongoing evolution within this sector. As industries increasingly adopt digitized manufacturing techniques, the demand for environmentally friendly, efficient operational solutions will only intensify. This transition towards automated systems not only streamlines processes but also paves the way for more sustainable manufacturing practices, enabling companies to adapt to the changing landscape of production and consumer expectations.

Unlocking the Future of Manufacturing: How CNC Precision is Revolutionizing Industries

| Industry | CNC Applications | Benefits | Future Trends |

|---|---|---|---|

| Automotive | Part production, Tooling | Increased precision, Reduced waste | Integrating AI for predictive maintenance |

| Aerospace | Component fabrication, Assembly | Enhanced safety, Lightweight designs | Growth in 3D printing technologies |

| Medical Devices | Implant creation, Surgical tools | Customization, Increased sterility | Advancements in bio-compatible materials |

| Electronics | Circuit board milling, Enclosure design | High accuracy, Reduced lead times | Emerging IoT integration in devices |

Case Studies: Successful CNC Implementation Across Various Sectors

CNC precision technology is being increasingly adopted across various sectors, revolutionizing the manufacturing landscape.

Case studies highlight successful implementations in industries such as automotive, aerospace, and even healthcare.

For instance, in automotive manufacturing, the integration of machine learning within the

Quality 4.0 PMQ framework

has notably improved process monitoring, leading to significant reductions in defects by up to

30%.

This efficiency not only lowers costs but also enhances the overall quality of products.

Tips: When considering CNC implementation, focus on training staff to effectively operate and integrate new technologies. Moreover, always assess the return on investment (ROI) by tracking efficiency metrics before and after CNC integration. Engaging your team in the transition process can significantly ease the implementation and encourage innovative applications of CNC technology.

Related Posts

-

5 Essential Tips for Choosing the Best CNC Machining Parts

-

7 Essential Benefits of Best Cnc Machining Precision in Modern Manufacturing

-

5 Reasons Why Best CNC Manufacturing Leads to Exceptional Product Quality

-

Exploring the Unique Features and Applications of Diverse Cnc Machining Alternatives for Global Buyers

-

Ultimate Guide to Comparing the Leading CNC Milling Machines for Global Buyers

-

Real-World Applications of Best CNC Machining: How Precision Manufacturing Transforms the Aerospace Industry