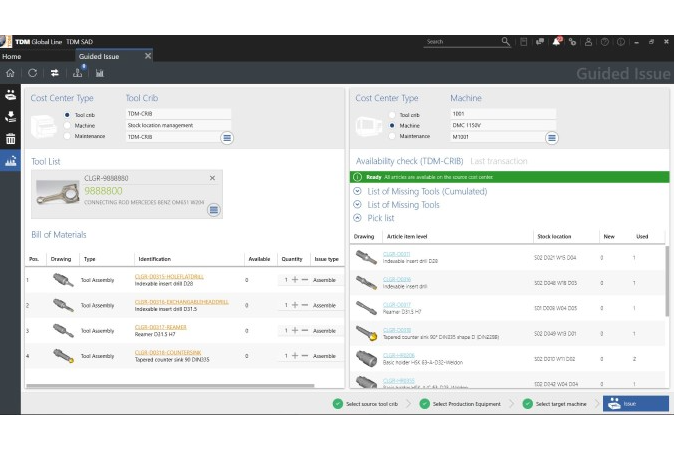

Inventory control made easy with our tool crib management system

The TDM crib facilitates clearly structured and cost-conscious control of the entire flow of production equipment. The intuitive minimum stock check facilitates prompt order management. The availability check reduces tool-related machine downtimes to a minimum.

The module offers intelligent analyses for optimum inventories. Users can also maintain an overview of tool usage with the informative evaluations. This makes overstocking a thing of the past.

-

The structure of the crib and cost centers has a variable configuration

-

The intuitive operation guides users through all booking dialogs

-

The module facilitates a connection to automated crib systems or vending machines

-

TDM takes into account both new and used articles, and users can define wear parts

-

With the main function users can book new entries and movements of the tools between crib, production costs centers, and repairs, as removals including stating the reasons

-

Users can make bookings at various data levels: From individual items, through tool assemblies and their parts lists, all the way up to complete tool lists and difference lists

-

With access to crib, there is an option to integrate ID systems, such as barcodes or chips

-

Crib controlling offers transparency through creating of statistics