Overview

Advantages of Digitalisation

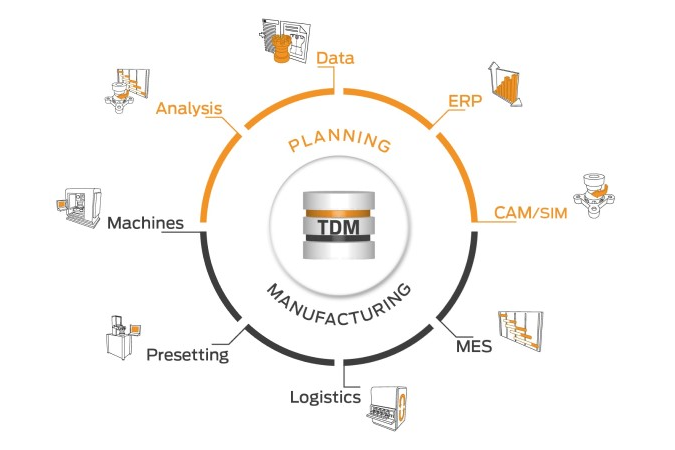

For over 30 years, TDM has been used to assist machining companies across the world with digitalising their production. With the TDM tool management solutions for machining, you can prepare your tool data in an application-oriented manner and record it centrally in a database.

All employees – in planning and production – working with the same data allows synergies to emerge and eliminates additional expenses due to entering the same data multiple times into different systems. With TDM solutions you always have an overview of your planning and production data.

Increase your productivity with these modules for the machining industry

1. Software for production equipment management

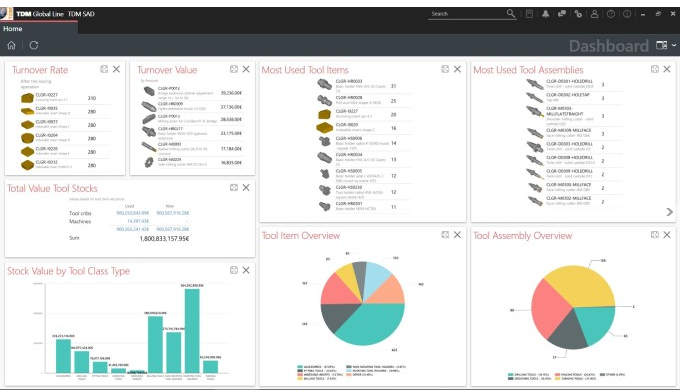

Do you not only want to record production data and resources quickly and easily, but also find them again? The TDM software for production equipment management simplifies your daily work with numerous coordinated modules. This enables you to organize your tools in all phases of planning and production as well as obtaining the best possible data transparency.

2. Software for shopfloor management

Have you captured all your data and your planning and manufacturing systems communicate smoothly thanks to TDM? Then digitalizing your shopfloor is a breeze! With the TDM software modules for shopfloor management, you always have an overview of your tool inventory, the condition and the current location of the tools. In this way you reduce tooling costs, save time during preparation and keep your production processes lean.

3. Software for graphics and data generation

If you want to fully exploit the potential of your Tool Data Management, you need a good database. TDM Systems offers you numerous solutions to capture new data in an application-oriented way or to enrich existing data with 2D and 3D tool graphics. With the new TDM WebCatalog and the TDM Data and Graphic Generators, this takes no time at all.

4. Interfaces

Independence from manufacturers is a key feature of TDM solutions. Interfaces link the different systems that are involved in your production process. They also stand for perfect integration: Numerous interfaces, many developed in cooperation with machine manufacturers or CAD specialists, guarantee smooth interaction and facilitate automated procedures in your production.

5. Data services – expert advice on your tool data

TDM Systems also offers the best solutions for tool data import and continuous data maintenance. After all, innovative, digital solutions are required to design data handling as easily and efficiently as possible. No matter whether solutions come from TDM or from partners, quality and easy handling are always in the forefront for us.

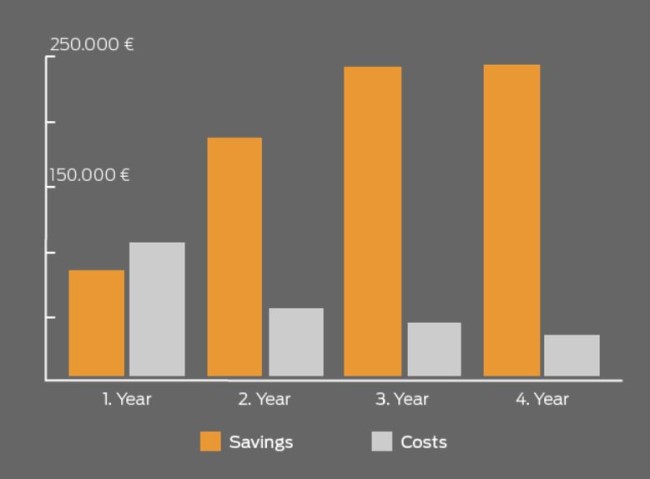

Productivity increase as a logical consequence

The use of TDM immediately turns potential savings into real savings. The tool procurement costs are significantly lowered by reducing the tool type variety and reducing hidden stocks. The management costs are lowered due to a reduced number of suppliers and the connections to ERP systems for an integrated ordering system. All in all, this leads to productivity increases for the customer of up to 20% annually.