Tool organisation on shopfloor level with the TDM Shopfloor Manager

Our software module includes a large number of functions that will also help optimise your shopfloor and its processes:

Shopfloor Designer

- The Shopfloor Designer configures the individual tool data flow in the individual shopfloor areas

- TDM provides a number of ready-made software operations, which result in status-led process control of the tool circulation

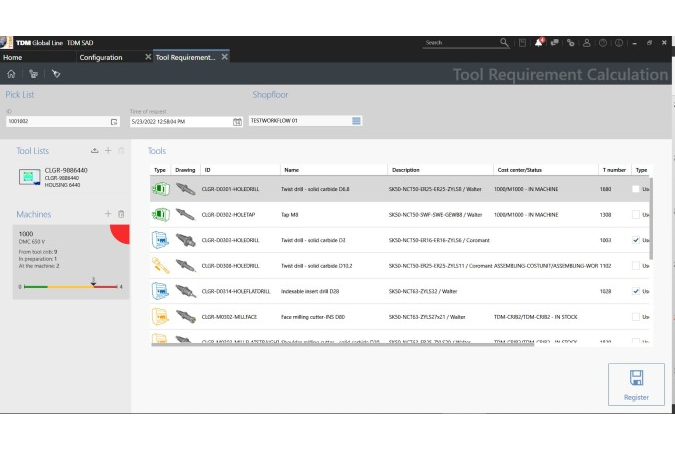

Demand calculation

- Tool provision is based on the tool requirements of the machines

- The software module enters the calculated tool requirements in a pick list

- ERP or MES systems transfer the production orders via interfaces

- The unloading list displays tools that are no longer needed on the machine

- The shopfloor organization records externally generated demand lists in parallel and processes these further as pick lists

- Standard interfaces to production control systems of various manufacturers are used to transfer the demand lists

Shopfloor navigation

- The Shopfloor Navigator generates the scope of functions and the operator processes from the configuration

- The Shopfloor Manager Global Line depicts the work areas as cost centers, whereby the module activates the operations for provision of tools executed in this based on status

- Users can distribute individual areas, such as crib/assembly and presetting, to various workplaces, as well as merging these in a Tool Room

Integration of machines (optional)

- The Shopfloor Manager considers real machine stocks and conditions of the tools, which helps with tool planning

- Optional integration of suitable subsystems and machines

- Reliable transfer of tool data (tool offsets)

- Demand planning considers the real remaining tool life or conditions of the tools, which facilitates optimum tool life management

- Automated operations, such as requests for Duplo tools and ad-hoc provision on the machine, simplify processes on the shopfloor