Measuring Software

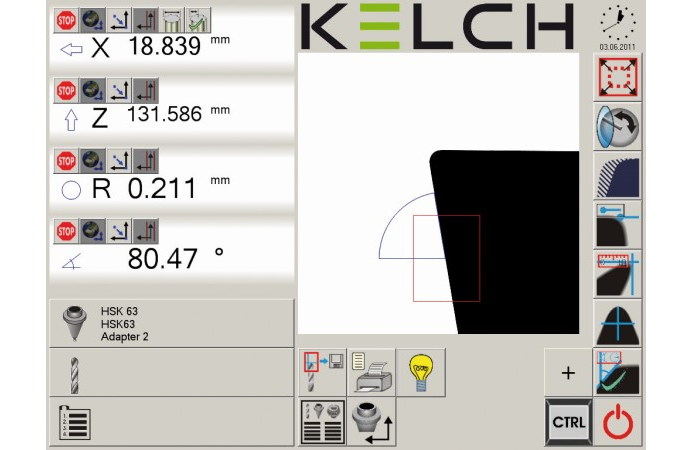

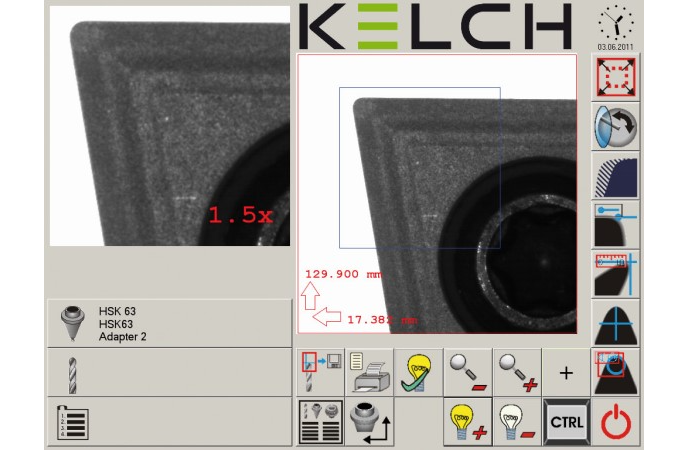

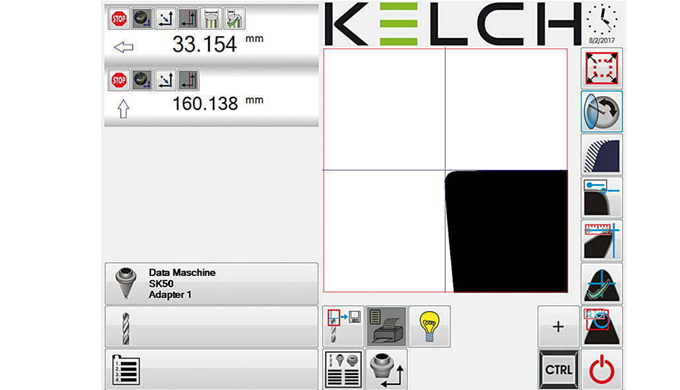

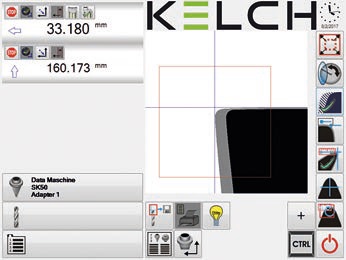

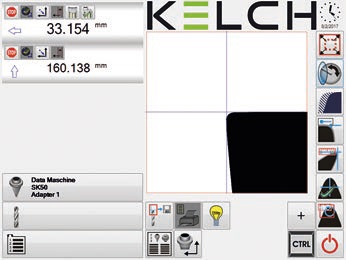

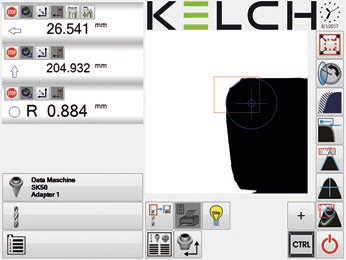

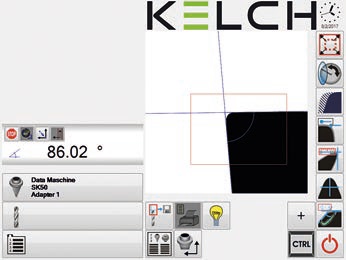

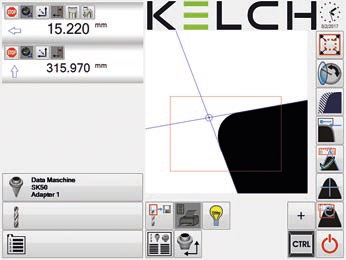

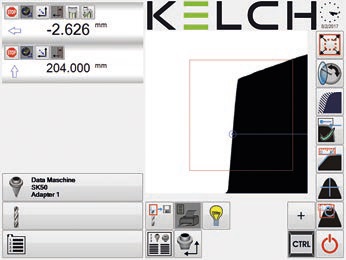

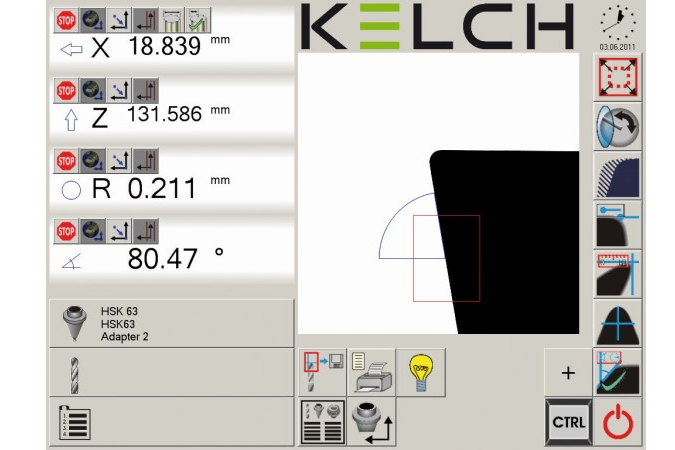

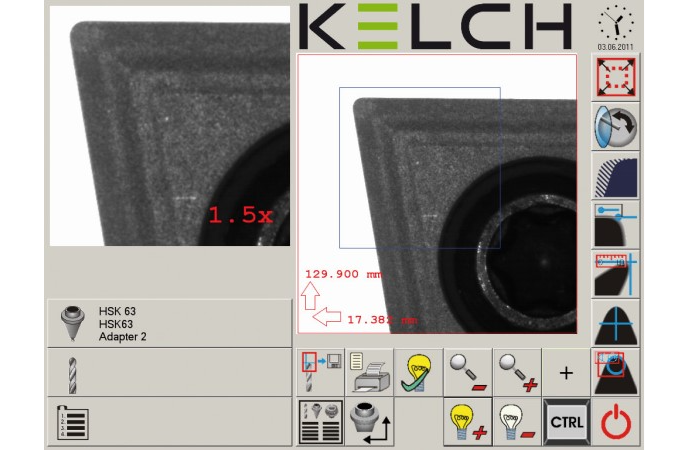

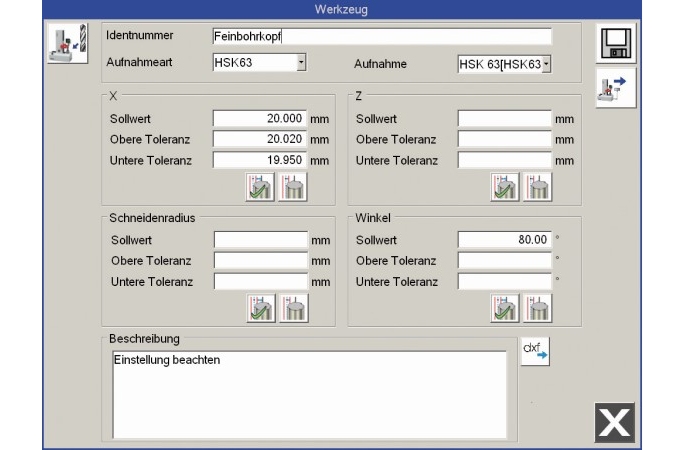

CoVis Software

Description

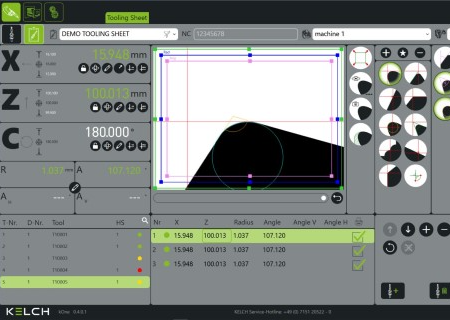

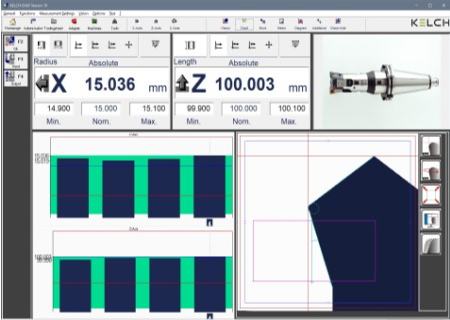

KELCH CoVis Software - Simple and Precise Results

Fast, reliable and easy to use without the need of extensive training – these are the requirements that users place today on small control units in order to master the everyday measuring and presetting tasks.

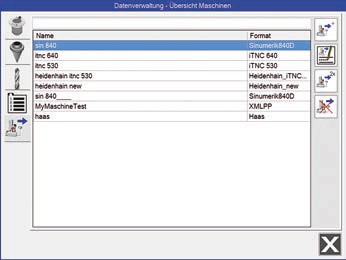

The intelligent touchscreen CoVis measurement control is also available with DNC data output to transfer measured values directly to the CNC machines, preventing potential input errors.