Technical

Optional Integration Solutions - Fit for Industry 4.0!

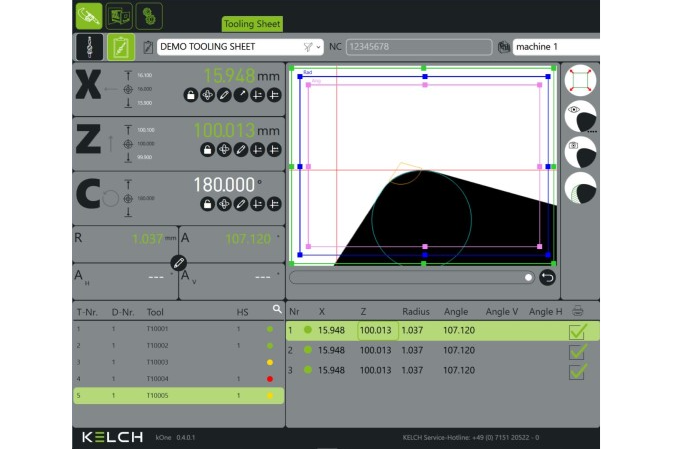

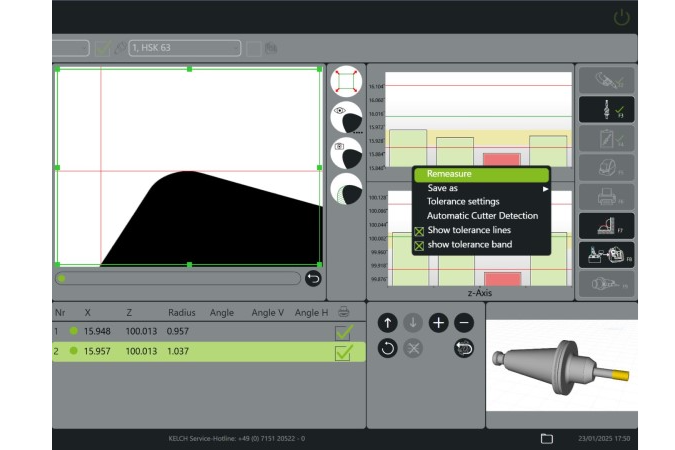

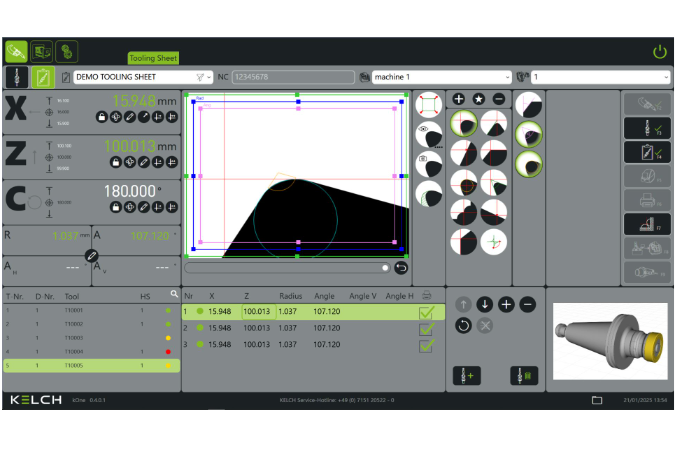

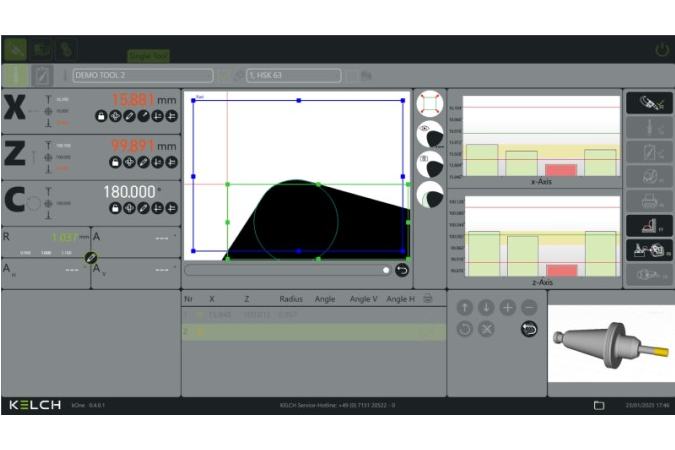

The KELCH kOne measuring software ensures that you can always save tool-based data and transmit it to the right place. It does not matter whether the data comes from machine controls, tool management programs, CAD/CAM systems or other manufacturing systems.

Interfaces are available using the following technologies and systems:

RFID Chip Systems

(Balluff, Euchner, Pepperl & Fuchs...)

Store tool ID, measured values and other machine-specific data on an RFID chip mounted to the tool holder

QR-Code, Data Matrix or Barcode Systems

Store tool ID, or complete set of measurement and machine-specific data on a 2D QR-code

DNC File Transfer

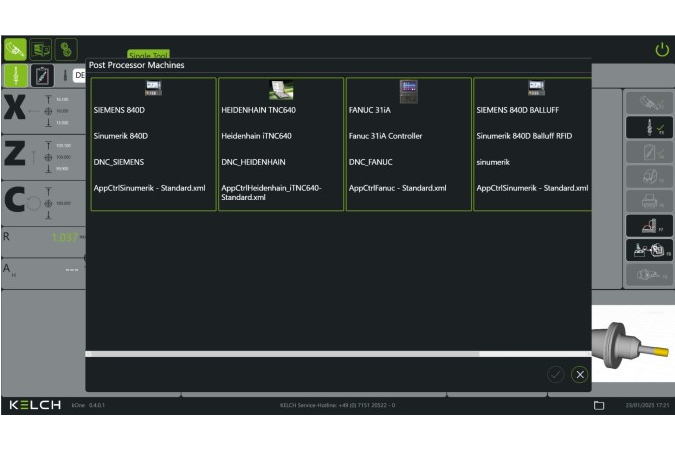

(Tool offsets to Heidenhain, Siemens, Fanuc...)

Package up your tool measurement data along with machine-specific data into a formatted text file or tool table and transfer directly to the machine via network, or through a separate DNC system

Third Party System Interfaces

(TDM System, Fastems, Mazak Smooth/CPC, Fastems, CosCom...)

Standard interfaces are available to a range of common tool management and manufacturing execution system which provide a secure 2-way process for transferring your data

Errors caused by incorrect input can be ruled out by sending the measured results directly to the machine control by post-processor via the network. This greatly enhances the process reliability and production efficiency. Along with the inclusion of tool identification this makes a significant contribution to process security when providing digital data exchange within your smart factory.

Using RFID or QR-code technologies greatly improves process reliability by having your tool and measurement data stored on the physical tool. Tools can easily be identified with the click of a button, and data can be transferred directly into the machine controller each time the tool is loaded into the magazine. RFID data chips have the additional benefit of being able to retain residual tool life once a tool is removed from the magazine, therefore improving tool utilisation.