Measuring Software

EASY Software

Description

MEASURING MADE EASY!

The KELCH EASY measuring software for tool presetters is an industry-proven and mature software platform for Windows PC systems, benefitting from advanced third-party system integrations to improve process reliability and production efficiency.

The software features a vast array of measuring functions with an intuitive navigation system requiring minimal training. Additional software modules are also available for accurately measuring special tools such as angled heads and profiling cutters.

CONTACT US FOR MORE INFORMATION ON THIS PRODUCT

CONTACT USOverview

Measuring made easy

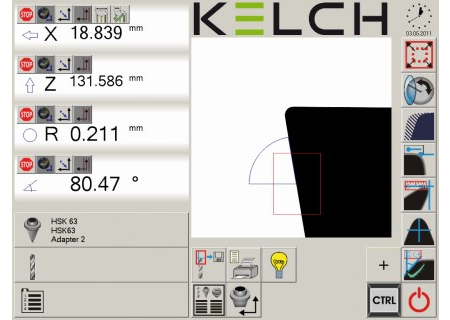

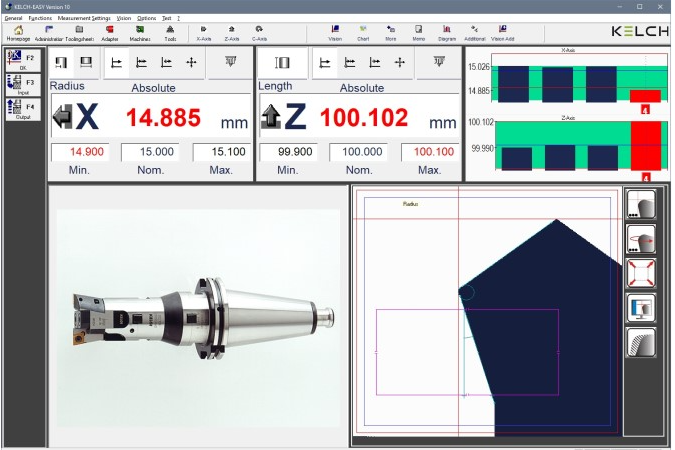

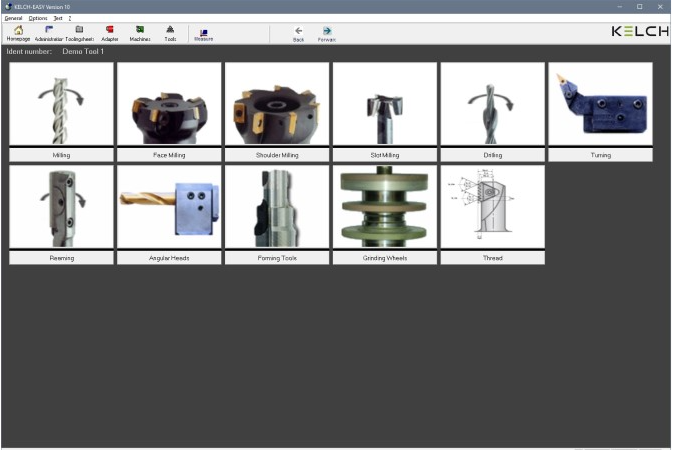

Measuring simply could not be easier with this software – and no special knowledge is needed. The clearly arranged user interface enables users to immediately navigate around the system using familiar forward/backward movements. A simple clear homepage is the direct entry to each measuring task. Other input screens, such as Picture Start, guide users step by step to the correct measuring result and also to the automatic measuring program. Adapters, machines, original tool forms, tooling plans and measuring processes are saved in the integrated database. The standard configuration includes bidirectional data communication (DNC) via a network card or serial interfaces in the KELCH data standard.

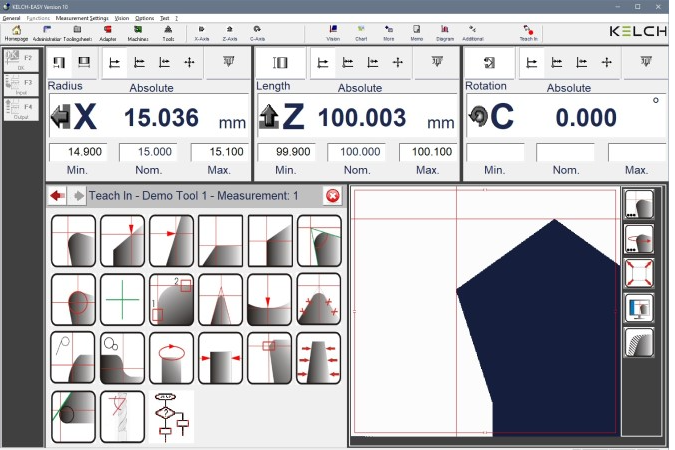

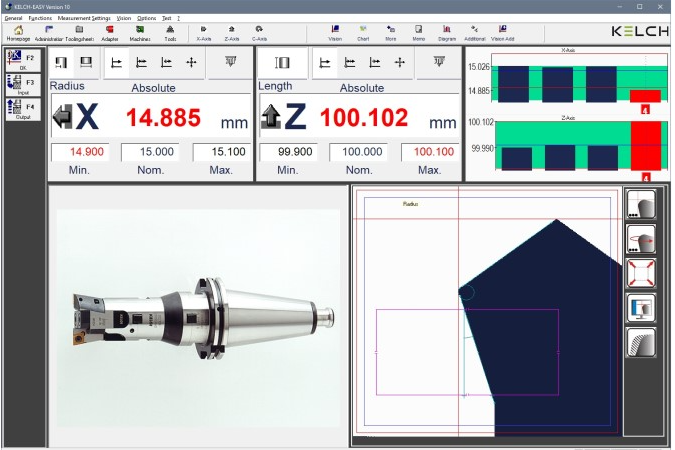

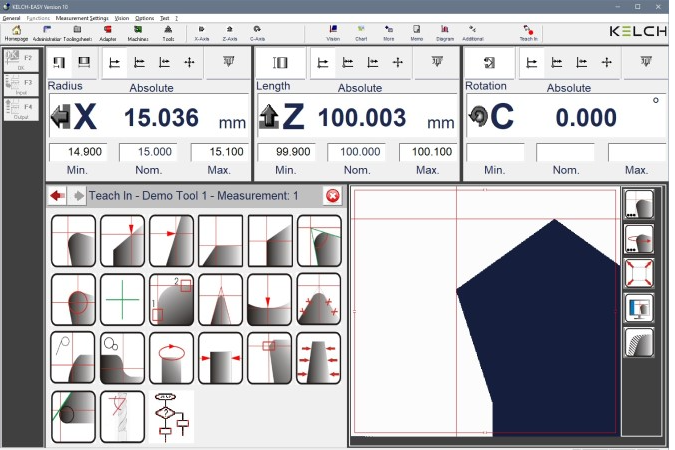

Automatic measuring programs

Complex tools can be measured fully automatically for the first time with the Teach-in software option. Fully automatic measurement guarantees precise measuring results and enables tool presetters to be operated regardless of the operator's knowledge and expertise. All measuring steps are retained and can be saved as a complete measuring program with the tool. EASY leads each user securely through the program with Picture Start using concise, easily understandable input dialogs. Practical pictures and graphics help with navigation and orientation.

Step 1:

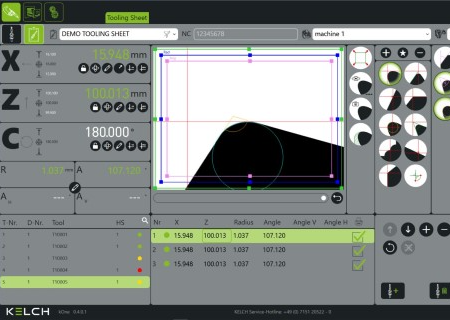

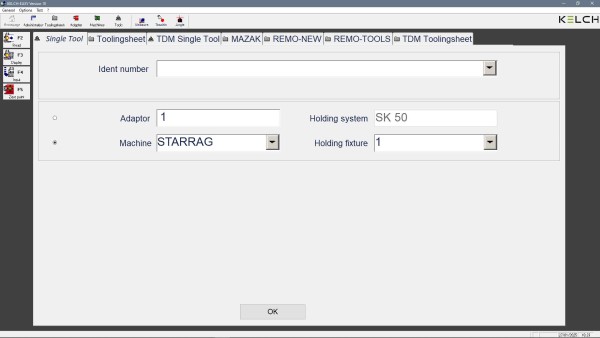

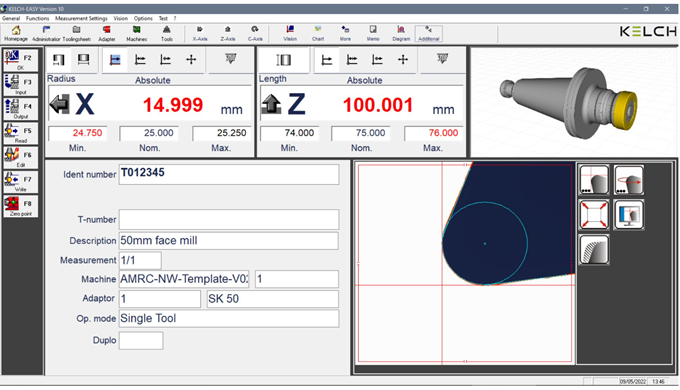

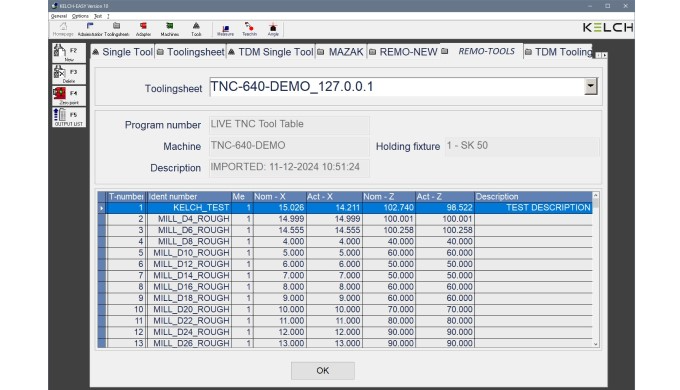

Input the measurement of individual tools or entire tooling sheets on the homepage. Then select the appropriate adapter on the tool presetter. If one of the tools entered has already been saved, the system calls it up by its identification number and immediately begins the measuring process.

Step 2:

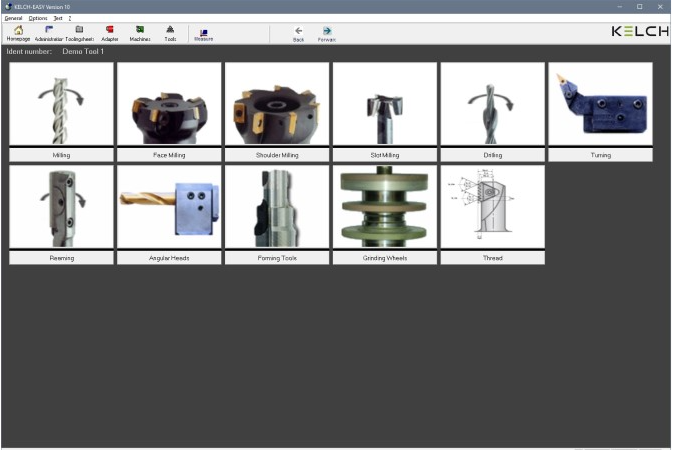

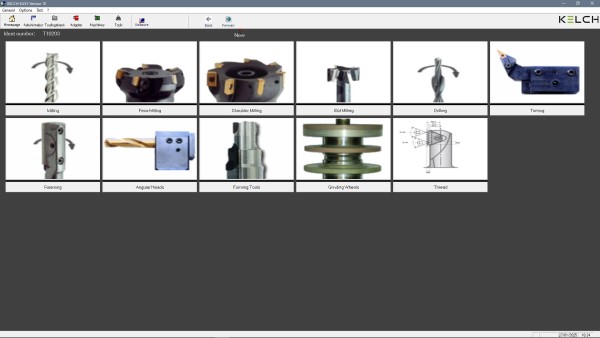

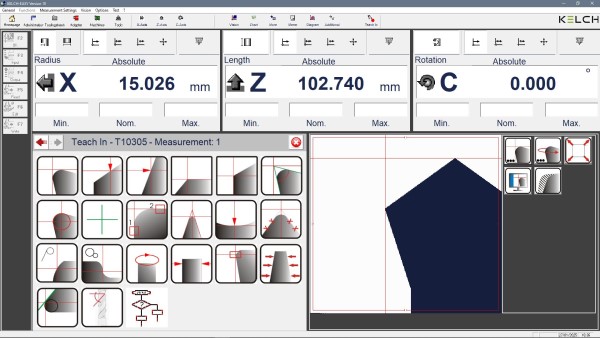

Select a tool using Picture Start. The selected tool then performs the measurement. Picture Start is KELCH's own in-house developed selection menu. Define the tool group you require using the different graphics. Simply click on the right graphic depending on the tool type and cutting geometry.

Step 3:

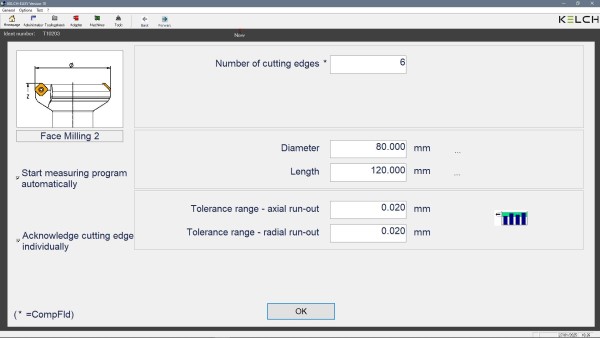

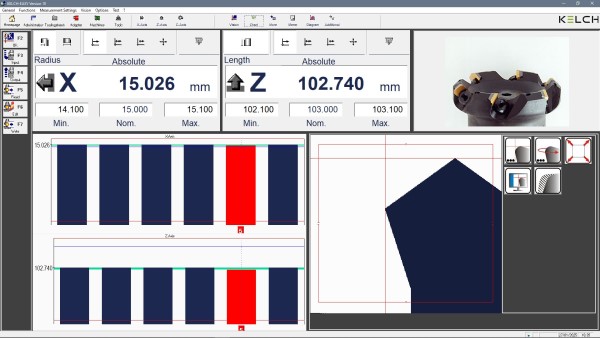

Use ParaDirect (PaD) for inputting data. This is a concise, easy-to-understand input dialog into which you enter the target dimensions and tolerances. Simply complete the mandatory fields for the measuring process. The corresponding measuring process begins when you have confirmed by pressing Enter. The data is entered from the PaD and the required measurement results are instantly available. Any actions required are clearly visible on the monitor.

Step 4:

The measuring process begins as soon as the identification number has been entered on the homepage (step 1). The process starts automatically if a measuring run has already been entered or read from RFID chip.

It couldn't be EASIER

The graphical user interface in the EASY software delivers the most precise measuring results and is easy to use and understand. The familiar Home-Forward-Back navigation is similar to the method used in most browsers, meaning that you can return to the starting point by pressing just a single button. The EASY software also comes with online Help, which is simple to understand and structured in a similar way to standard Windows applications.

The graphical user interface in the EASY software delivers the most precise measuring results and is easy to use and understand. The familiar Home-Forward-Back navigation is similar to the method used in most browsers, meaning that you can return to the starting point by pressing just a single button. The EASY software also comes with online Help, which is simple to understand and structured in a similar way to standard Windows applications.

Software Updates

The EASY measuring software is always evolving with new features and functions. The software can easily be updated to match the latest Windows operating system architecture, which increases the longevity of your presetting software. Contact us now for more information regarding the latest version of the EASY measuring software.

Image

Technical

Optional Integration Solutions - Fit for Industry 4.0!

The industry-proven KELCH EASY measuring software ensures that you can always save tool-based data and transmit it to the right place. It does not matter whether the data comes from machine controls, tool management programs, CAD/CAM systems or other manufacturing systems. With EASY we have dozens of "off-the-shelf" interface solutions ready and available to connect with your external system. Due to the flexible design of the software, it is also possible to develop a customised integration or special process which is tailored to your specific requirements.

Interfaces are available using the following technologies and systems:

RFID Chip Systems

(Balluff, Euchner, Pepperl & Fuchs...)

Store tool ID, measured values and other machine-specific data on an RFID chip mounted to the tool holder

Store tool ID, measured values and other machine-specific data on an RFID chip mounted to the tool holder

QR-Code, Data Matrix or Barcode Systems

Store tool ID, or complete set of measurement and machine-specific data on a 2D QR-code

DNC File Transfer

(Tool offsets to Heidenhain, Siemens, Fanuc...)

Package up your tool measurement data along with machine-specific data into a formatted text file or tool table and transfer directly to the machine via network, or through a separate DNC system

Third Party System Interfaces

(TDM System, Fastems, Mazak Smooth/CPC, Fastems, CosCom...)

Standard interfaces are available to a range of common tool management and manufacturing execution system which provide a secure 2-way process for transferring your data

Errors caused by incorrect input can be ruled out by sending the measured results directly to the machine control by post-processor via the network. This greatly enhances the process reliability and production efficiency. Along with the inclusion of tool identification this makes a significant contribution to process security when providing digital data exchange within your smart factory.

Using RFID or QR-code technologies greatly improves process reliability by having your tool and measurement data stored on the physical tool. Tools can easily be identified with the click of a button, and data can be transferred directly into the machine controller each time the tool is loaded into the magazine. RFID data chips have the additional benefit of being able to retain residual tool life once a tool is removed from the magazine, therefore improving tool utilisation.

Image

Options

The KELCH EASY software has a number of additional modules available for more specialised applications, including:

PictureStart Module

A graphical programming module that offers pre-defined measuring cycles for standard types of tools, with a simple setup process.

TeachIn Module

An advanced process-driven measuring program module for creating customised measuring cycles for simple and complex tools.

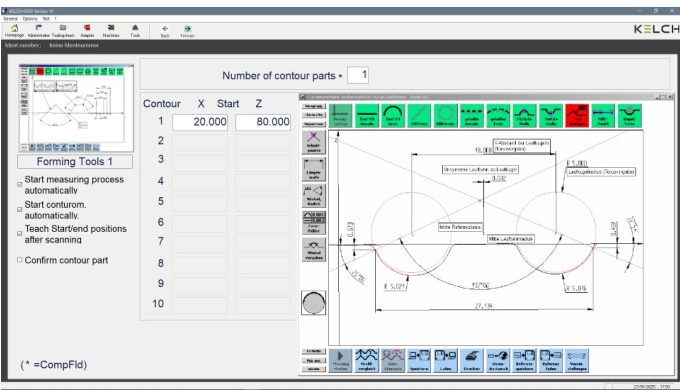

Contour Module

An independent software which connects to EASY and facilitates scanning of complex tool profiles with independent measurement analysis and comparison to a template model.

3D-Wizard

Where the need to produce a 3D image from the measured values this module meets that objective.

Tool Exchange Module

For customers who have multiple KELCH presetters and wish to synchronise the data between them, this module can deliver powerful results and eliminate redundant data. If tool data or a measuring program is amended on one presetter, this change is instantly reflected across all connected presetters (with EASY software) via network communication.

TDM Interface

This forms the standard interface between the Tool Presetter and the industry leading TDM Tool Data Management Software for importing and exporting tool data and actual values.

RFID Module

Where RFID tags or data chips are used on the tool holders, this module controls the read/write functions and data format.

Angle Heads Module

The Angled Heads Module for EASY accommodates the storing and processing of gauge lengths and angles for accurately measuring any type of angled tooling. It also allows the measuring crosshairs to be automatically adjusted to match the measuring orientation of each specific angled head tool.

Second Camera

For turning camera and using a swivel head camera this module controls the second image.

Monitor Configuration

The EASY software comes as standard on a single 24" monitor. However, we also offer a number of monitor sizes and options including:

- 24" touchscreen main monitor

- 2x 24" monitors (either vertical or horizontal) with an enlarged camera window on the second display

- Additional 10" monitor fitted to rear of camera arm with an enlarged camera window for clear visbility

Image