BENEFITS OF PRESET TOOLS

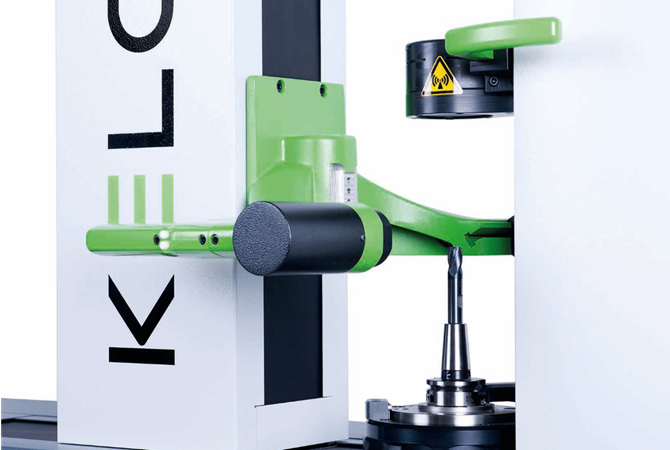

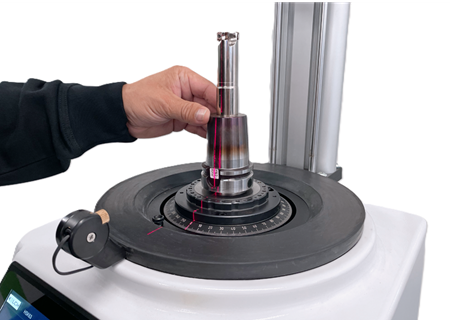

Automatic Measuring with High Res Cameras

Non Contact Micron Accurate

Using high definition camera technology to measure and inspect cutting tool assemblies, removes the operator involvement in the process. This gives greater repeatability and eliminates human error.

INCREASE PRODUCTIVITY

Preset tools will save down time on your machines, reduce associated costs and improve overall productivity. Investment in a tool presetter will prove cost effective and have a surprisingly short ROI.

YOU MAY ALSO NEED

SET LINE V9-S

SET LINE V3

SET LINE V6

SET LINE V9

SET LINE H3

SET LINE CUSTOM

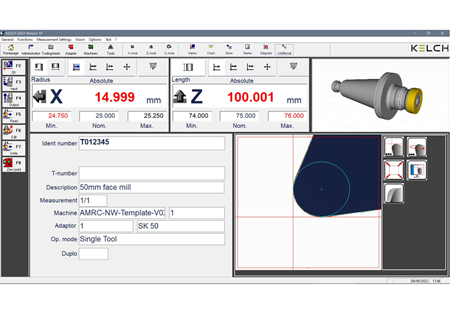

EASY WEBSET SOFTWARE

DATA TRANSFER

ACCESSORIES

SET LINE V2

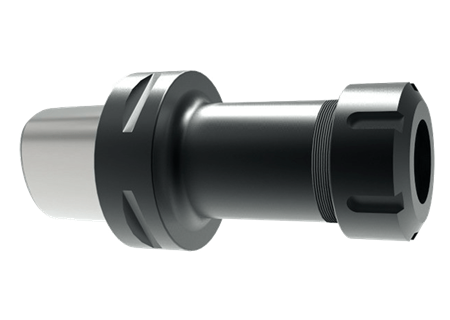

SK Holders

BT Holders

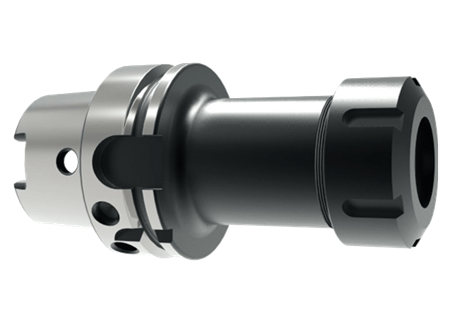

HSK Holders

PSC Holders

MANUAL SHRINK

SEMI-AUTOMATIC SHRINK

AUTOMATIC SHRINK PREMIUM LINE

Tool Storage

Tool Transportation

Tool Crib Design

Safecontrol 4.0

Safecontrol 2

Kelch Control

Production Facility

Spindle Pull Force 4.0

Pull Force Gauge 2.0

Gauges

Flexibore

BALANCING TB100

Tool Balancing TB200

Balancing

More KELCH

TDM Overview

AUTOMATIC SHRINK ISG3410

Test arbors

Measuring Software

What is Tool Data Management?

Why Use Tool Data Management?

TDM Base Module

TDM Crib Module

TDM Shopfloor Manager

TDM Interfaces

TDM-KELCH Presetter Interface

TDM Tool Data

Tool Balancing

Tool Shank Cleaner

Tool Holder Accessories